Both air-screen cleaning machines and air-screen gravity separators are used for material cleaning.

Working Principle

Air Screen Cleaner: Primarily utilizes the difference in geometric size and suspension velocity between seeds and impurities for cleaning. Material is conveyed to a bulk grain bin via a lifting device, dispersed into a uniform waterfall surface, and enters a vertical air screen. Airflow generated by a blower draws light impurities such as rice husks and dust into a settling chamber for centralized discharge. The remaining material flows into a vibrating screen, where it passes through screens of different sizes, separating large and small impurities according to particle size.

Air Gravity Separator: Combines the advantages of air screening and gravity separation. First, light impurities are removed by the air screen. Then, utilizing the principle of gravity separation, based on the difference in specific gravity between the material and impurities, under the combined action of the vibrating screen surface and airflow, the lighter impurities are distributed on the surface and flow downwards, while the heavier, better material is distributed at the bottom and flows upwards, thus achieving finer separation.

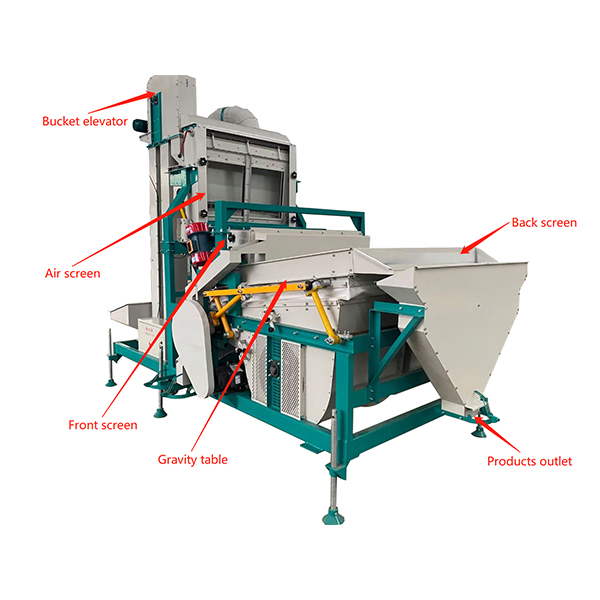

Structural Composition

Air Screen Cleaner: Typically consists of a screening device, an air separation device, an electrical control device, and a support structure.

Air Screen Gravity Separator: Based on the air screen cleaner, this model adds components such as a gravity separator.

Cleaning Effect:

Air Screen Cleaner: Effectively removes large, small, and light impurities from materials, meeting general cleaning needs. However, its cleaning effect is limited for impurities with similar specific gravity to the material, such as immature grains and moldy grains.

Air Screen Gravity Separator: Due to the added gravity separation function, it can more accurately separate impurities with different specific gravities, such as shriveled seeds, sprouted grains, insect-damaged grains, and moldy grains, resulting in higher cleaning purity. It can be used in seed processing or grain grading scenarios with high cleaning requirements.

Applications: Air Screen Cleaner: Suitable for initial and basic cleaning of crop seeds such as wheat, corn, and rice. It can also be used for preliminary screening and cleaning of various grain crops, small oilseed crops, and various beans.

Applications:Air-screen gravity separator: Suitable for screening, cleaning, and grading grains, oil crops, and various beans with high purity requirements, especially suitable for commercial grain processing and seed processing industries with strict material quality requirements.

Equipment Features: Air-screen gravity separator: Features small footprint, simple operation, and convenient cleaning. Multiple crops can be cleaned by changing the screen plates.

Air-screen gravity separator: Typically integrates air screening, gravity separation, and vibration cleaning into one unit, offering more comprehensive functions and better cleaning results. However, the equipment structure is relatively complex, occupies a larger area, and has relatively higher energy consumption.

Both air-screen cleaners and gravity separators belong to the category of grain and legume cleaning equipment, with the core design goal of removing impurities and improving material purity. Both can be used for cleaning and processing various grains and legumes such as wheat, corn, rice, soybeans, miscellaneous grains, and oil crops, and can be adapted to materials of different particle sizes by changing the screen plates, exhibiting strong material compatibility.

Both types of equipment use air separation + screening as their basic cleaning module.

Air Separation Section: Both utilize a fan to generate airflow, based on the difference in suspension velocity between the material and light impurities (such as dust, shriveled husks, and broken straw), blowing away and collecting the light impurities.

Screening Section: Both are equipped with multi-layer vibrating screens. By changing the screen plates with different aperture sizes, based on the difference in geometric size between the material and large/small impurities, large impurities (such as stones and large straw) are separated into small impurities (such as mud, sand, and broken particles).

The core structural components of the equipment overlap. Both include basic components such as a feeding system, air separation system, screening system, discharge system, electrical control system, and frame. The design logic and function of the air separation system’s fan, air duct, and settling chamber, and the screening system’s vibrating motor, screen frame, and screen plates are completely identical.

Post time: Dec-26-2025