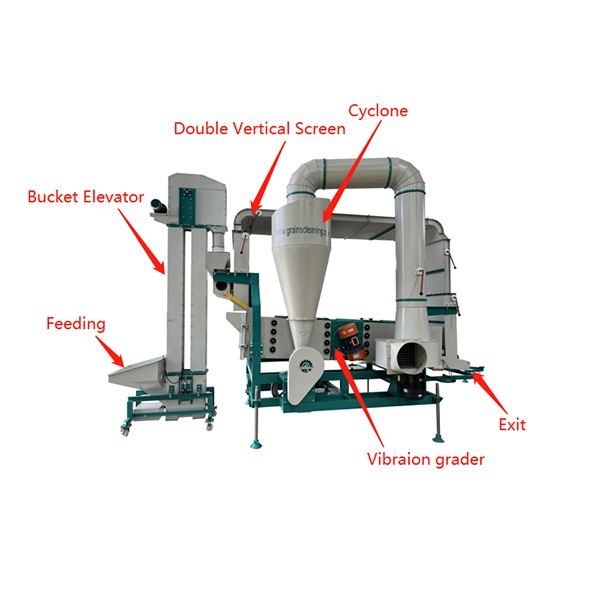

The double air screen cleaning machine is a machine that cleans and grades impurities in grains, beans, and seeds such as sesame and soybeans, and removes impurities and dust.

Working principle of double air screen cleaner

(1)Air separation principle: Utilizing the aerodynamic characteristics of granular materials, the airflow generated by the vertical air screen makes the light impurities and heavy materials in the materials produce different movement trajectories under the action of the airflow, thereby realizing the separation and removal of light impurities.

(2)Screening principle: After winnowing, the material enters the vibrating screen. The vibrating screen adjusts the precision punching screen pieces of different specifications according to the size of the material, so that large impurities are left on the screen surface and removed, small impurities fall through the screen holes, and the materials that meet the requirements are discharged from the corresponding outlet. At the same time, the finished materials can be divided into large particles, medium particles and small particles by increasing or decreasing the number of layers of the screen pieces.

2、Advantages of double air screen cleaner

(1)Good cleaning effect: The double air screen design is used to perform two air separations, which can more thoroughly remove light impurities in the material. It has a significant effect on crops with high light impurity content, such as sesame and soybeans. At the same time, the dust generated by the crushing of soil blocks during the vibration screening process can also be secondary air separation, which enhances the brightness of the finished product.

(2)High processing purity: Through the dual effects of wind selection and screening, as well as the adjustable precision punching screen, various impurities such as large impurities, small impurities, and light impurities can be effectively removed, which greatly improves the purity of the finished product and meets the requirements of different users for material purity.

(3)High production efficiency: The large screen surface design can increase the processing capacity of materials, thereby improving production efficiency and meeting the needs of large-scale production.

(4)Strong versatility: One machine can be used for multiple purposes. By replacing screens of different specifications, it can be used to winnow, screen and grade grains of various crops and agricultural and sideline products, reducing the customer’s equipment investment cost.

(5)Easy operation and maintenance: The structural design of the equipment is reasonable, and some parts are connected by bolts, which is convenient for disassembly and installation, and daily inspection and maintenance. At the same time, the equipped control device also makes the operation simpler and more convenient, and easy for staff to master.

Our machines clean harvested wheat, corn, soybeans, sesame and other commercial grains, removing impurities such as straw, sand, dust, and insect-eaten grains. The cleaning effect is good and the quality is guaranteed.

Post time: Jul-20-2025