In the entire process of peanut grading and screening, “feeding and pre-cleaning” is the key link between raw materials and core grading. The quality of its operation directly determines the subsequent grading accuracy (such as avoiding screen blockage and reducing mixed grades) and equipment stability.

1. Raw Material Pretreatment Inspection: Preemptively eliminate “high-risk impurities” to reduce equipment risks.

Before peanuts enter the grading screen feed system, they must undergo preliminary inspection and pretreatment to prevent large, hard impurities (such as branches and metal pieces) from damaging the equipment or clogging the screen. This includes: raw material appearance inspection and impurity screening, and raw material moisture testing.

2. Feeder Debugging: Match the equipment’s processing capacity to avoid “material pile-up” or “material breakage.”

The grading screen feed system typically consists of a raw material bin, conveyor belt, and buffer divider. Debugging is required to ensure the feed rate matches the grading screen’s processing capacity. Specific steps include:

Raw material bin and conveyor belt debugging, and buffer divider debugging.

3. Uniform Feeding Operation: Real-Time Monitoring to Stabilize Material Flow

After commissioning is complete, the formal feeding phase begins. Dedicated personnel must monitor the feed flow in real time to ensure a stable flow. Key operational points:

Feeding startup sequence (to avoid equipment shock)

Follow the “downstream first, upstream last” principle: Start the grading screen first (to ensure the vibration system is functioning properly) → Start the air separation and pre-cleaning device → Start the conveyor belt → Slowly open the discharge valve of the raw material bin to prevent accumulation of raw materials at the grading screen inlet.

Real-Time Monitoring and Adjustment

Observe the thickness of the material layer on the upper screen of the grading screen.

4. Air Separation and Pre-cleaning Operation: Separate Light Impurities and Reduce the Classification Burden

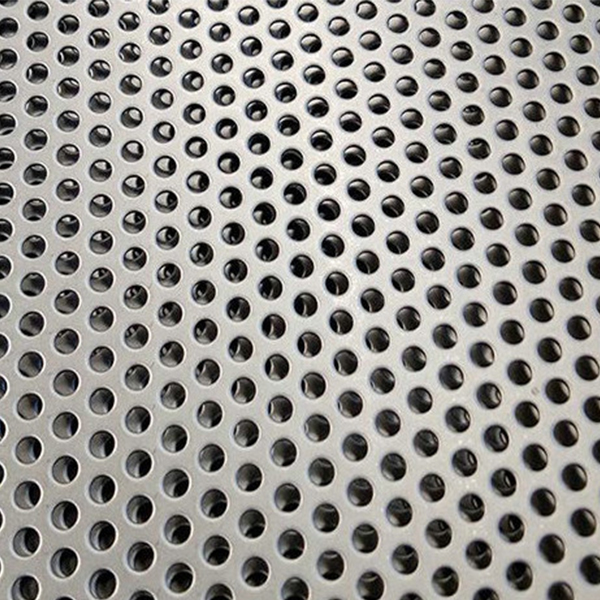

Most grading screens have an integrated “air separation and pre-cleaning device” below the feed inlet, which uses airflow to separate light impurities (such as broken shells, fluff, and dust) from the peanuts.

5. Abnormal situation handling: quick response to avoid equipment damage

Through these standardized operations, we achieve “stable peanut feeding + efficient pre-cleaning,” providing clean, uniform raw materials for the subsequent core grading process while minimizing equipment failures and improving overall processing efficiency. Taobo grading machine is suitable for grading and cleaning a variety of bean materials. Contact us now if you need it!

Post time: Oct-09-2025