The cleaning process of the Taobo grading machine follows the core logic of “pretreatment → multi-layer screening → air separation and impurity removal → finished product output”. Through the automated process, impurities are accurately separated from high-quality peanuts. The specific steps are as follows:

1. Raw Material Pretreatment: Initially removes impurities to reduce equipment burden.

Feeding: Peanuts to be cleaned (including dirt, broken shells, shredded kernels, weeds, and other impurities) are evenly fed into the feed port of the grading screen via a conveyor belt or hopper. The feed rate can be adjusted via a PLC control system to prevent screen clogging due to excessive feeding.

Preliminary Filtration: Raw materials first pass through a “pre-screen” (pore size approximately 10mm) at the feed port to quickly filter out larger impurities such as stones, large pieces of dirt, and long weeds, preventing them from entering the subsequent grading stages and damaging the screens or affecting cleaning accuracy.

2. First-tier Grading Screen: Removes coarse impurities and selects large particles.

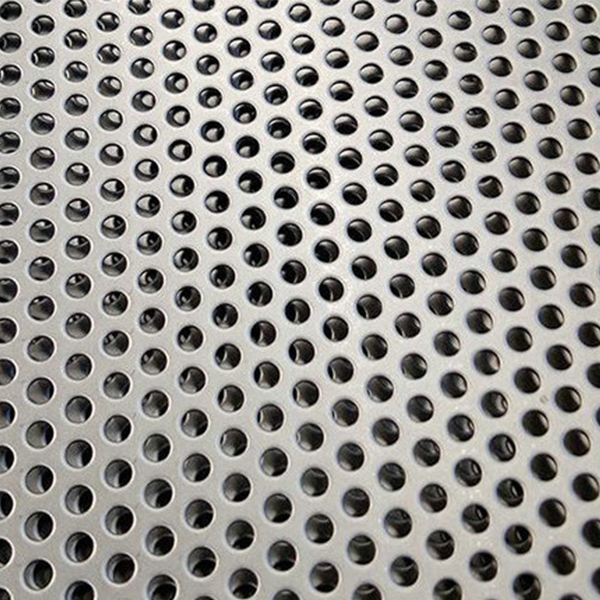

Screen Configuration: The first tier uses a rigid metal screen with a pore size of 6mm (wear-resistant and non-deformable), which accommodates the particle size range of most peanut varieties.

Separation: The peanuts vibrate gently at high frequency (approximately 3-5mm in amplitude) with the screen. Smaller peanuts, broken pieces, and fine impurities pass through the screen gaps and fall into the second layer. Larger impurities (such as intact shelled peanuts and unshelled small peanuts) that fail to pass through are discharged along the screen’s inclined surface through the “coarse impurity outlet,” completing the initial separation.

3. Second-layer grading screen: Separates broken and partially shrunken peanuts, purifying medium-sized particles.

Screen Configuration: The second layer features a flexible nylon screen with a 3mm aperture (excellent elasticity to prevent peanuts from impact and breakage).

Separation: From the material falling from the first layer, partially shrunken peanuts, fine broken pieces, and dust pass through the 3mm slits and enter the air separation channel below. Full, standard-sized peanuts (typically 3-6mm) remain on the screen surface and are transported by vibration to the third layer, completing the secondary separation of “medium-sized impurities from standard-sized peanuts.”

4. Third-tier Grading Screen: Screening for High-Quality Finished Products and Controlling Fullness

Screen Configuration: The third tier utilizes an “adjustable aperture flexible screen” (changeable to 4-5mm aperture according to customer needs) and is equipped with a slow-speed conveyor (conveying speed 0.8 m/s).

Separation Function: Peanuts conveyed from the second tier are further screened by the screen while moving slowly. A small number of semi-full peanuts with smaller diameters pass through the slits and merge with the crushed peanuts falling from the second tier. High-quality peanuts with a diameter and fullness that meet the standards (over 95%) pass along the end of the sieve and enter the “finished product temporary storage bin,” completing the core grading and screening process.

The entire process requires no human intervention, from raw material input to finished product output. A single unit can process 15 tons of peanuts per hour, ensuring both precision and efficient continuous operation, perfectly meeting the large-scale production needs of peanut processing companies. Our grading machine can be used to screen and remove impurities from a variety of materials, such as soybeans, mung beans, coffee beans, and chickpeas. Choosing our taobo machines means choosing peace of mind.

Post time: Sep-19-2025