The Beans grader machine & grading machine it can used for beans, kidney beans, soya beans, mung beans, grains.peanuts and sesame seeds.

This Beans grader machine & grading machine is to separate the grain, seed and beans to different size. Only need to change the different size of stainless steel sieves.

Meanwhile it can remove the smaller size impurities and larger impurities further, There are 4 layers and 5 layers and 8 layers grading machine for you to choose.

Choosing the right grading screen for cleaning beans revolves around three core matching principles: bean characteristics, processing requirements, and equipment compatibility. Key parameters include screen mesh, sieving method, and throughput.

Core Selection Criteria:

Identify Bean Type and Characteristics:Determine the screen mesh size range based on bean particle size (e.g., soybeans, mung beans, red beans). Soft beans should be protected from high-intensity vibration to prevent damage.

Match Processing Capacity Requirements: Select equipment specifications based on actual hourly/daily processing capacity to avoid overloading small equipment or wasting energy with large equipment.

Determine Sieving Accuracy Requirements: For multi-grade grading (e.g., 3 or more grades), choose a multi-layer screen; for only impurity removal and coarse grading, a single-layer/double-layer screen is sufficient.

Adapt to Subsequent Processing: For subsequent peeling and color sorting, prioritize vibrating grading screens (for uniform grading); high-impurity raw materials can be paired with equipment featuring pre-screening.

Key Equipment Parameter Selection

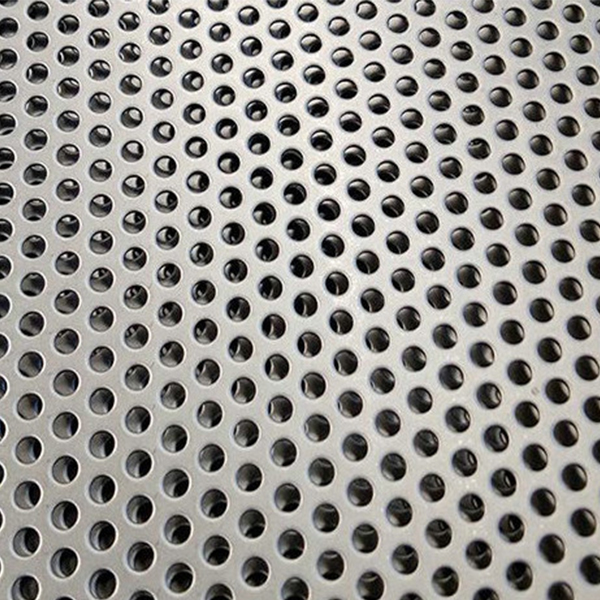

Screen Material: Stainless steel is preferred (corrosion resistant, easy to clean, and meets food standards) to avoid rust and contamination from ordinary wire mesh.

Screening Method: Vibrating (suitable for most beans, high efficiency, and accurate grading)

Number of Screen Layers: 4-8 layers are available; more layers result in finer grading. Selection should be based on the actual number of grading grades required.

Adjustment Flexibility: Choose equipment with adjustable screen angle and vibration frequency to easily adapt to different beans and precision requirements.

The core of sieve selection is: determining the sieve aperture based on the bean particle size, selecting the material and mesh type based on the bean characteristics, and matching the grading requirements (impurity removal/grading).

Core Selection Principles: Based on bean particle size: The sieve aperture should be slightly smaller than the minimum particle size of the target bean (for impurity removal), or a gradient aperture should be set according to grading levels (for grading) to avoid sieve leakage or clogging.

Adapting to Bean Physical Characteristics: Rigid mesh can be selected for hard beans (such as soybeans and chickpeas), while flexible mesh can be selected for soft/fragile beans (such as kidney beans and lentils) to reduce particle breakage.

Matching the Sieving Purpose: For impurity removal only, a single-layer sieve with the corresponding aperture size is selected; for multi-grade grading, a multi-layer gradient aperture sieve (with apertures gradually decreasing from top to bottom) is selected.

Recommended sieve parameters for common beans:

Soybeans: Particle size approximately 4-6mm, use a 4-mesh (4.75mm aperture) pre-sieve for impurity removal + an 8-mesh (2.36mm aperture) fine sieve; grading can be done in 3 grades (5 mesh, 6 mesh, 7 mesh).

Mung beans: Particle size approximately 3-4mm, use a 6-mesh (3.35mm aperture) + 10-mesh (2.00mm aperture) sieve for impurity removal; grading can be done at 7-mesh, 8-mesh, and 9-mesh gradients.

Red beans/Mung beans: Particle size approximately 2.5-3.5mm, use an 8-mesh (2.36mm aperture) + 12-mesh (1.70mm aperture) sieve for impurity removal; grading can be done at 9-mesh, 10-mesh, and 11-mesh.

Kidney beans/flat beans: Approximately 5-8mm in diameter. Use 3 mesh (6.70mm aperture) + 6 mesh (3.35mm aperture) to remove impurities. Choose woven mesh for its soft texture to avoid scratches from perforated mesh.

Additional Considerations:

Cleanliness and Maintenance: Prioritize equipment with easily removable screens and no unsanitary corners to reduce the risk of residual contamination.

Energy Consumption and Noise: For food processing applications, choose equipment with low noise (≤85dB) and energy-efficient motors.

Durability: Check the structural strength of the screen body and the quality of the motor to avoid long-term vibration that could cause parts to loosen and become damaged.

Most time the air screen cleaner will as the Pre-cleaner in the sesame processing plant or beans processing plant, For the grader is will be used in the processing plant, as the final machine to separator the good beans or coffee beans or grains to be different size.

For our clients demands, we will make sure the suitable solution for you, so that you will use the correct machine for you business.and we can grow up together.

Post time: Nov-19-2025