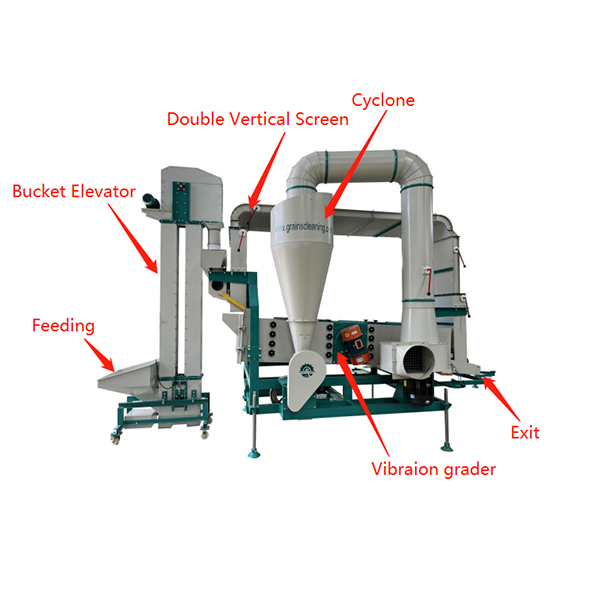

The air screen cleaner and grains cleaner it can remove the dust and light impurities by vertical air screen , Then vibrating boxes can remove the big and small impurities , and Grains and seeds can be separated big ,medium and small size by different sieves . and it can remove the stones .

The core steps for replacing the screen of an air-screen cleaning machine are: “power off and stop the machine → disassemble the fixing parts → remove the old screen → install the new screen → reset and check”. The operation is simple and requires no special tools.

I. Preparations Before Replacement

First, disconnect the main power supply to the equipment and ensure the motor is completely stopped to avoid accidental restarting during operation.

Prepare a new screen of the matching model (select the screen aperture size according to the particle size of the material to be cleaned), wrenches, screwdrivers, and other basic tools, as well as gloves (to prevent hand cuts).

Clean up any residual material and impurities around the screen box to avoid interfering with the replacement operation.

II. Core Replacement Steps

Open the screen box access door: Locate the screen box access door on the side or top of the equipment, loosen the door lock or fixing bolts, and open it directly.

Remove the old screen fixing parts: The screen is usually fixed to the screen frame by bolts, pressure strips, or clips. Use tools to unscrew the bolts one by one (or unlock the clips), remove the pressure strips, and gently remove the old screen from the screen frame.

Clean impurities from the screen frame: Wipe the edges of the screen frame with a brush or cloth to remove residual dust and material debris to prevent impurities from affecting the sealing of the new screen installation.

Install the new screen: Lay the new screen flat on the screen frame, ensuring it is smooth and wrinkle-free, and that the screen openings are aligned with the cleaning process (avoid reverse installation).

Secure the new screen: Replace the pressure strip, align it with the bolt holes, and evenly tighten all bolts (or fasten the clips). Use moderate force to ensure the screen is securely fixed while preventing the pressure strip from damaging the screen edges.

III. Post-Replacement Inspection

Manually pull the screen to confirm there is no looseness or displacement, and that there are no gaps between the screen and the frame.

Close and lock the inspection door. After connecting the power, run the machine unloaded for 3-5 minutes, observing whether the screen vibrates evenly and whether there are any abnormal noises or deviations.

Introduce a small amount of material for a trial run to check if the cleaning effect is normal. If there is no leakage or incomplete separation of impurities, it is ready for formal use.

The air-screen cleaning machine is suitable for a wide range of materials, primarily adaptable to various granular and lumpy grains and cash crops, and can also process some industrial granular materials.

Main Applicable Material Types:

Grain Crops: Wheat, corn, soybeans, rice, sorghum, millet, barley, oats, etc., removing impurities such as straw, stones, dust, and shriveled grains.

Oil Crops: Peanuts (with shell/shelled), rapeseed, sesame, sunflower seeds, cottonseed, etc., cleaning impurities and assisting in grading, suitable for the pre-processing needs of oil pressing plants.

Miscellaneous Grains: Buckwheat, millet, sorghum, red beans, mung beans, kidney beans, and other small-particle miscellaneous grains, separating impurities such as soil, broken shells, and empty grains.

Seeds: Various crop seeds (such as corn seeds, soybean seeds, vegetable seeds), screening and grading, removing impurities, and improving seed purity.

Post time: Nov-12-2025