The core principle of selecting screen plates for an air-cooled screen cleaning machine is “matching material particle size + adapting to cleaning requirements.” Different materials require different screen plate apertures, aperture shapes, and materials based on particle size, shape, and impurity type.

Core Principles of Screen Plate Selection:

Aperture Matching Material Particle Size: The screen aperture size should be slightly larger than the average particle size of the target material to ensure the passage of qualified material while intercepting impurities.

Aperture Shape Matching Material Shape: Round apertures are suitable for spherical/near-spherical materials, and elongated apertures are suitable for flat/strip-shaped materials, avoiding screen clogging or inaccurate grading.

Material Matching Material Characteristics: Thickened perforated screens are selected for abrasive materials, woven screens for fine materials, and anti-clogging screen plates are selected for moist materials.

Specific Selection of Screen Plates for Common Materials

1. Grains (Wheat, Corn, Rice)

Wheat: Primarily use round-hole screen plates. The upper coarse screening layer has a 3.5-4.0mm aperture (blocks large impurities), the middle grading screening layer has a 2.2-2.8mm aperture (retains clean grains), and the lower fine screening layer has a 1.0-1.5mm aperture (filters fine impurities).

Corn: Both round and oblong holes are acceptable. The upper coarse screening layer has a 6.0-8.0mm aperture (blocks straw and large stones), and the middle grading screening layer has a 4.5-5.5mm aperture (separates plump grains from shriveled grains). Thickened perforated screens are recommended for wear resistance.

Rice: Oblong-hole screen plates are better suited to the flat, elongated shape of the grains. The upper coarse screening layer has a 4.0-5.0mm aperture, and the middle grading screening layer has a 2.5-3.0mm aperture to avoid clogging of the round holes.

2. Legumes (soybeans, peas, pigeon beans)

Soybeans: Use round-hole sieves. The upper coarse screening layer has 5.0-6.0mm apertures (to remove large impurities), and the middle grading layer has 4.0-4.5mm apertures (to select plump beans). Stainless steel perforated sieves are preferred (corrosion resistant).

Peas: For near-spherical materials, use round-hole sieves. The upper coarse screening layer has 5.5-6.5mm apertures, and the middle grading layer has 4.5-5.0mm apertures. In humid environments, chamfered sieves (to prevent sticking) can be used.

Pigeon beans: Use round-hole sieves. The upper coarse screening layer has 4.5-5.5mm apertures, and the middle grading layer has 3.8-4.2mm apertures. Sift thickness should be 1.2-1.5mm (to enhance wear resistance).

3. Grains (Millet, Sorghum, Buckwheat)

Millet: Due to its small size, use a fine-mesh sieve with round holes. The upper coarse sieve should have a 2.0-2.5mm aperture, and the middle grading sieve should have a 1.5-1.8mm aperture. A woven sieve is recommended for high sieving accuracy.

Sorghum: Use a sieve with round holes. The upper coarse sieve should have a 3.5-4.0mm aperture, and the middle grading sieve should have a 2.8-3.2mm aperture. Avoid using sieves with overly large holes that could trap broken grains.

Buckwheat: For flat grains, use a sieve with long holes (5.0-6.0mm long diameter, 3.0-3.5mm short diameter) to ensure smooth passage of buckwheat and prevent impurities from being trapped.

4. Oilseeds (Rapeseed, Peanuts, Sesame)

Rapeseed: Small, round particles. Use a woven sieve with round holes. The upper coarse sieve has a 1.8-2.2mm aperture, and the middle grading sieve has a 1.2-1.5mm aperture (to filter small impurities).

Peanuts (with shells): Use a long-aperture sieve with a long diameter of 12-15mm and a short diameter of 8-10mm. The upper coarse sieve blocks large impurities, and the middle grading sieve separates peanuts of different sizes.

Sesame: Extremely fine particles. Use a high-mesh woven sieve. The upper coarse sieve has a 1.0-1.2mm aperture, and the middle grading sieve has a 0.8-1.0mm aperture. The sieve should be made of stainless steel (to prevent rust and contamination).

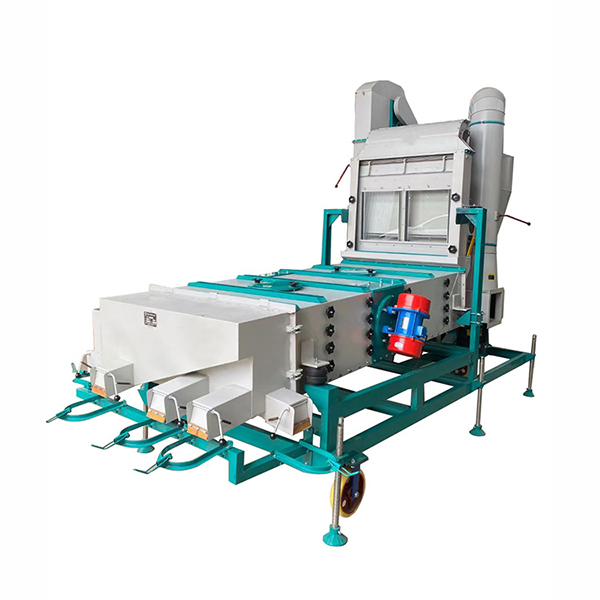

The air-screen cleaner is the core component of grain and legume cleaning equipment. Its core value lies in “high-efficiency impurity removal + basic grading,” directly determining the quality of subsequent processing, equipment safety, and product quality. It is adaptable to various material processing needs: by adjusting the screen plates and air speed, it can be adapted to different materials such as wheat, corn, soybeans, and miscellaneous grains, offering high flexibility and making it an essential piece of equipment for comprehensive grain and legume processing lines.

Post time: Nov-10-2025