In the process of removing impurities from mung bean crops, gravity machines and grading screens are two commonly used equipment. They have different focuses and use different principles to achieve impurity separation and material screening.

1、The function of specific gravity machine

The specific gravity machine (also known as specific gravity separator) mainly uses the difference in specific gravity (density) between materials and impurities for separation. It is suitable for removing impurities that are similar in size and shape to mung beans but have different specific gravity. The specific functions include:

(1)Separation of light and heavy impurities: remove light impurities with a specific gravity less than that of mung beans, such as dust, shrunken grains, insect-eaten grains, straw debris, grass seeds, etc.; remove heavy impurities with a specific gravity greater than that of mung beans, such as pebbles, mud, metal debris, etc.

(2)Purify the quality of mung beans: It can effectively separate imperfect grains (such as immature grains and diseased grains) from mung beans, improve the fullness and uniformity of the finished mung beans, and meet the quality requirements for processing or sales.

2、The role of grading machine

The grading screen (also known as the screening machine) mainly uses the differences in particle size and shape between materials and impurities for separation, and achieves grading and impurity removal through screens of different apertures. The specific functions include:

(1)Grading by particle size: Screening mung beans into different grades (such as large, medium, and small) according to particle size for subsequent processing (such as peeling, grinding) or graded sales.Remove impurities larger than the size of mung beans, such as large stones, whole pods, straw segments, etc.Remove impurities smaller than the size of mung beans, such as fine sand, broken bean powder, small grass seeds, etc.

(2)Separation of impurities with obvious shape differences: Impurities with shapes that are very different from mung beans (such as slender grass stems and flaky bean skins) can be separated by the vibration trajectory of the screen even if the particle sizes are similar.

Specific gravity machine: The core is “separation by density”, which solves the problem of impurities of similar size but different specific gravity.

Grading screen: The core is “separation by size/shape”, which solves the problem of impurities with similar specific gravity but different sizes.

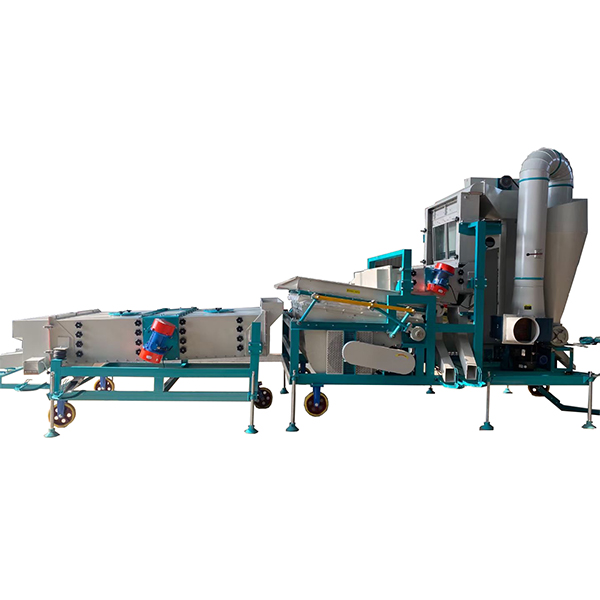

In actual production, the two are often used in combination: first, impurities with obvious volume differences are removed through a grading screen, and then impurities with obvious density differences are separated through a specific gravity machine, forming a “coarse and fine combination” impurity removal process to maximize the purity and quality of mung beans.

Post time: Jul-25-2025