Peru, as the country of origin of quinoa, has long ranked first in the world in terms of quinoa planting area and output. However, it is mainly based on small-scale, scattered farming by individual farmers, and the yield per unit area is limited by natural conditions. Air-screen cleaning machines play an irreplaceable role in the quinoa cleaning process, reducing labor costs, improving quinoa quality, and ensuring industry standardization.

Quinoa Cultivation in Peru:

Peak Scale: Peru leads the world in quinoa cultivation. According to data from the UN Food and Agriculture Organization (FAO) in 2024, Peru’s quinoa cultivation area reached 131,000 hectares in 2023, with a yield of approximately 102,000 tons, accounting for 54.8% of global production. It ranks first in the world in both cultivation area and yield. However, its yield per unit area is only about 0.78 tons/hectare, which is somewhat insufficient, mainly due to the poor soil and inadequate irrigation facilities in some areas of the Peruvian highlands.

Cultivation Model: Primarily Small-Scale Farming: About 70% of the country’s quinoa is produced by small family farms in the Andes Mountains. These farms have an average plot size of less than 2 hectares. Because small farmers cannot afford expensive large-scale agricultural machinery, planting, harvesting, and initial processing have long relied on manual labor or simple equipment. Subsequent processing is often done through cooperatives to connect with buyers and exporters, thus integrating them into the quinoa industry chain.

The growing regions are well-suited to quinoa’s growth habits: Quinoa originates from the high-altitude mountains of the Andes Mountains, and thrives best at altitudes of 3,000-4,000 meters in plateaus or mountains. Quinoa cultivation in Peru is also concentrated in areas that meet these growing conditions, leveraging the region’s cool climate and large diurnal temperature variations to ensure the basic quality and stable growth of the quinoa.

The industry relies on organic certification to enhance competitiveness: As a traditional major producer, Peru emphasizes strengthening the premium pricing power of its quinoa products through an organic certification system. Currently, organic quinoa exports account for 42% of global exports, and Peru, with its native growing advantages, holds a significant position in the organic quinoa market, making it one of the core competitive advantages of its quinoa industry.

Quinoa cleaning is a core intermediate step from field harvesting to end-consumer/export, directly determining the quality, value, safety, and industrial scale of quinoa. Its importance runs through the entire chain of “farmer income – product circulation – industrial competitiveness”.

I. Ensuring Food Safety and Avoiding Health Risks

Quinoa naturally contains harmful impurities after harvesting. If not thoroughly cleaned, direct consumption during processing or after harvesting poses clear risks:

Field Impurities (Soil, Gravel, Small Stems, Weed Seeds): Consuming these may damage the digestive system. Gravel can also abrade processing equipment (such as grinders and hullers), indirectly introducing secondary contamination such as metal shavings.

Moldy Particles and Insect-Infested Seeds: The high-altitude growing environment makes quinoa prone to mold growth. If not removed, the toxins produced by mold (such as aflatoxin) can harm human health and contaminate the entire batch of quinoa.

One of the core purposes of cleaning is to remove all harmful and worthless impurities, ensuring that the quinoa meets food hygiene standards and is suitable for various scenarios, including home use, supermarkets, and deep processing.

II. Enhancing Product Quality and Creating Premium Value

The core competitiveness of quinoa lies in its “purity and grain uniformity,” and cleaning is a crucial prerequisite for quality improvement, directly impacting product pricing:

Purity determines basic quality: Uncleaned quinoa contains impurities, has a rough appearance and poor taste, and can only be used as a low-priced raw material; after precise cleaning (such as by air-screen cleaning machines), quinoa purity can reach over 98%, with plump grains free of impurities, meeting “food grade” and “export grade” standards, increasing the selling price by 30%-50% (especially for Peruvian organic quinoa, where purity is a mandatory indicator for export to European and American markets);

Grading increases added value: During the cleaning process, grain grading (large, medium, and small grains) can be achieved simultaneously. Large-grain quinoa can be used for high-end meal replacements and organic food exports, medium-grain quinoa for daily consumption, and small grains for feed or deep processing, avoiding the waste of value caused by “mixed-grade sales” and allowing farmers/enterprises to achieve “high quality, high price.”

The Importance of Air Screen Cleaners for Quinoa Cleaning

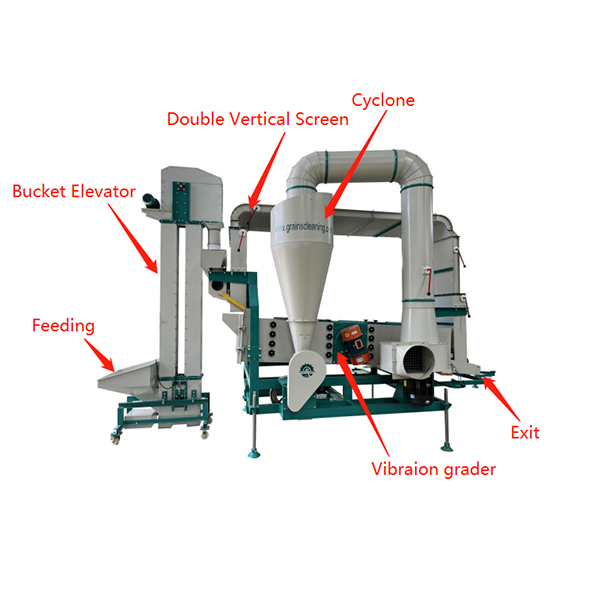

Significantly Reduces Labor Costs and Improves Cleaning Efficiency: Before the widespread adoption of air screen cleaners, smallholder farmers in Peru relied on manual labor to clean quinoa. This involved repeatedly beating the plants with long sticks to thresh the grains, followed by manually sorting impurities—a labor-intensive and time-consuming process. Air screen cleaners integrate air separation and screening functions, enabling batch processing of quinoa. Local cooperatives, for example, have significantly reduced their labor input for quinoa cleaning after adopting this equipment, resolving the pain point of low efficiency in manual cleaning for smallholder farmers.

Precise Impurity Removal Ensures Quinoa Purity: After harvesting, quinoa contains a large amount of dust, empty husks, shriveled seeds, and small stems. If these impurities are not removed, they will severely affect the quality of the quinoa. Air-screen cleaners use airflow to separate light impurities such as dust and empty shells, then use screens with different apertures to sift out shriveled seeds and small debris. Some machines even employ a three-layer sieve bottom and secondary air separation design, achieving high-precision impurity removal and significantly improving the purity of quinoa to meet the quality requirements of subsequent processing and export.

Aiding grading to meet diverse market demands: Air-screen cleaners can also grade quinoa based on particle size. After grading, uniformly sized quinoa can be sold to cooperatives for further processing or exported, while smaller particles can be kept as feed or for farmers’ own use. This grading function helps farmers accurately target different markets, improving the overall profitability of quinoa products.

Avoiding processing risks and supporting industry standardization: Manual cleaning is not only difficult to thoroughly remove impurities but may also introduce new impurities due to improper operation. Furthermore, inconsistent cleaning standards hinder the development of industry standardization. The standardized cleaning process of the air-screen cleaning machine can not only avoid problems such as screen blockage that affect the processing progress, but also keep the quality of quinoa stable, providing a key guarantee for Peruvian quinoa to enter the international market and meet the globally unified food processing standards.

If you have materials that need cleaning, please contact us. We professionally manufacture grain and bean cleaning machines of various specifications. Welcome to inquire and purchase online!

Post time: Dec-05-2025