1. Soybeans (Core Economic Crop for Both Countries)

Paraguay: Planting Scale: Approximately 3.6 million hectares in 2024/25, total output 10.2 million tons, main season soybeans approximately 9.29 million tons, secondary crop soybeans approximately 1.24 million tons.

Main Producing Areas: Eastern regions such as Alto Paraná and Canindeyu, yields can reach 6-7 tons/hectare; Chaco region is a newly expanded area, expected to expand from 100,000 hectares to 120,000 hectares in 2025/26.

Industry Characteristics: Accounts for approximately 18% of agricultural GDP, exports account for over 90%, mainly to Argentina and China.

Uruguay: Planting Scale: 1.3 million hectares in 2024/25, total output 3.837 million tons, yield 3.12 tons/hectare (historical high).

Main producing areas: Western provinces such as Soriano, primarily rain-fed. Exports reached US$1.199 billion in 2024, a year-on-year increase of nearly 200%.

Industry characteristics: Genetically modified varieties dominate; China is a major export market, with exports to China increasing fourfold year-on-year in 2024.

2. Beans (Regional staple food and minor trade crop)

Paraguay: Primarily for local consumption, often intercropped with corn and cassava. Yield is heavily influenced by smallholder management. Planting area has been steadily declining in recent years due to competition from soybeans.

Uruguay: Planting is concentrated in the south and west, mainly red and white kidney beans. Some are exported to Brazil and Argentina. Planting area slightly decreased in 2024/25 due to low international soybean prices.

3. Chickpeas (Niche specialty crop)

Neither country is a major producing area. Planting is scattered and small-scale, mostly dryland farming or on marginal land. Organic and traditional varieties are the main focus, primarily meeting local niche markets and food industry needs. There is no large-scale export data.

Key Differences and Trends

Soybeans: Paraguay has a larger planting area (approximately 2.7 times that of Uruguay), but Uruguay has higher yields, faster export growth, and a more mature multi-cropping model.

Lotus Beans/Chickpeas: Paraguay has a slightly larger planting area, while Uruguay has higher yields. Both countries are primarily self-sufficient, and their planting area is limited due to competition from major crops.

Technological Approaches: Both countries primarily use genetically modified soybeans, while their kidney beans/chickpeas are mostly traditional varieties. Uruguay is more proactive in variety approval and international market integration.

What cleaning equipment is typically used to remove these soybean impurities?

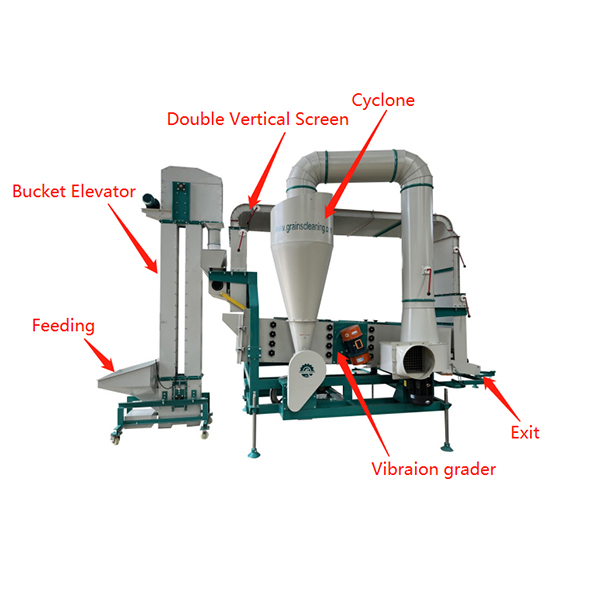

Soybean cleaning primarily follows a process of “air-screen combination + gravity destoner + color sorting/selection,” with equipment matched in the following order: “removing light impurities first → removing large and small impurities → separating heavy impurities → selection and grading → color sorting to remove damaged grains.”

Standard Cleaning Process and Equipment Combination:

Primary Cleaning: Magnetic separation (iron removal) → Primary cleaning screen (removing large and light impurities), processing high-impurity soybeans after harvest to reduce the load on subsequent equipment.

Main Cleaning: Air-screen cleaner → Gravity destoner (removing heavy impurities), removing over 90% of inorganic/organic impurities to meet basic processing requirements.

Selection: Grading screen → Color sorter (removing discolored/damaged grains), improving purity and quality, suitable for seed or export soybeans.

Auxiliary: Dust removal system (cyclone + bag filter), collecting dust to meet environmental protection requirements.

Selection Guidelines

Scale Matching: Small-scale systems use a mobile air screen + portable destoner; large-scale systems use an air screen cleaner + gravity separator + color sorter in tandem, with a processing capacity ≥ 100 tons/hour.

Impurity Types: For high levels of light impurities (mostly straw), prioritize enhanced air screening; for high levels of heavy impurities (stones/mud), a gravity separator is essential; for export/seed processing, use color sorting for finer selection.

Cost Balance: Primary cleaning should be air screening; secondary cleaning should include gravity separators; color sorting should be added for high-end applications, avoiding over-configuration.

Post time: Dec-30-2025