In the production and processing chain of grains and beans, the cleaning process is a key link to ensure product quality and enhance industrial value. For a long time, traditional grain and bean cleaning has relied on manual winnowing and simple sieve filtration, which is not only time-consuming and labor-intensive, but also inefficient. It is also difficult to completely separate impurities and substandard grains and beans, resulting in insufficient purity and poor appearance of the finished product, which seriously restricts farmers’ income and corporate competitiveness.

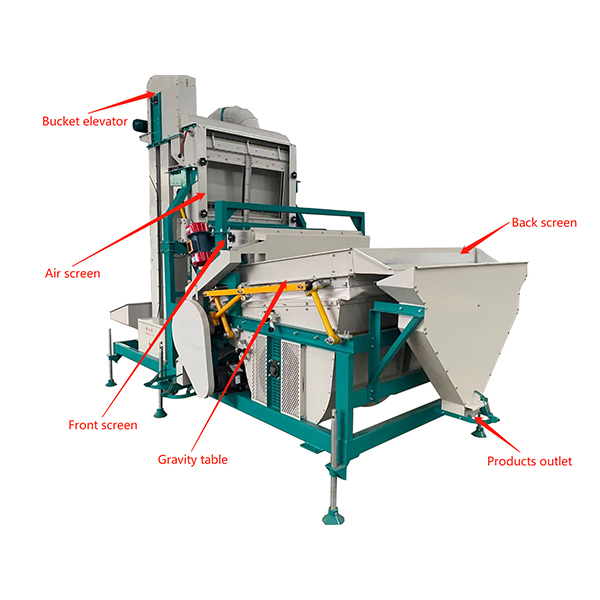

Our Taobo grain and bean air-screen and gravity cleaning machine, with its innovative integration of dual cleaning technologies (“air screening + gravity”), has completely broken the limitations of traditional cleaning and has become a core piece of equipment for improving quality and efficiency in the grain and bean industry. Its advantages lie in efficiency, precision, applicability, and affordability, fully meeting the cleaning needs of diverse users.

1. High-efficiency cleaning significantly improves production efficiency.

Under traditional manual cleaning methods, a skilled worker can only process a few hundred kilograms of grain and beans per day. Long hours of work can easily lead to fatigue, resulting in a continuous decline in cleaning efficiency. The grain and bean air-screen gravity cleaner, however, utilizes an automated, continuous-operation design. Combining a high-power fan with a high-frequency vibrating screen, it can process several to tens of tons of grain and beans per hour, achieving efficiency improvements of dozens or even hundreds of times greater than manual operation.

2、Precision Separation Ensures High-Quality Finished Products

Cleaning accuracy is a key factor in determining the value of grains and beans. The air-screen gravity cleaner achieves cleaning accuracy far exceeding that of traditional equipment through its combined “dual filtration + gravity classification” technology.

Air-screen filtration for efficient impurity removal: The device features a built-in multi-stage fan and adjustable damper, precisely controlling the air speed based on bean variety and impurity type (such as dust, straw, leaf fragments, and light, shriveled kernels).

Gravity classification for high-quality bean selection: Utilizing a gravity screening device, the device accurately separates plump, semi-plump, and shriveled kernels based on density differences.

3. Broad Applicability, Covering All Grain and Bean Categories

Unlike traditional single-category cleaning equipment, the Grain and Bean Air Screen Gravity Cleaner offers exceptional versatility. By flexibly adjusting parameters, it can accommodate nearly all common grain and bean varieties, including major grains like wheat, corn, rice, sorghum, and millet, as well as various types of legumes like soybeans, mung beans, red beans, peas, and kidney beans.

4. Economical and Durable, Reducing Long-Term Operating Costs

From an economical perspective, the Grain and Bean Air Screen Gravity Cleaner not only increases profits by improving efficiency and ensuring quality, but its durability and low maintenance also save users long-term expenses. The main unit is constructed of high-strength steel, the screen is made of wear-resistant manganese steel, and the fan and motor are high-quality industrial-grade components. They can withstand long-term, high-intensity operation and have a service life of 8-10 years, far exceeding that of ordinary simple cleaning equipment.

5. Intelligent and Convenient, Low-Operation Threshold

To suit diverse user groups, the grain and bean air-screen gravity separator strives for simple and intelligent operation. The device features a clear control panel, where key parameters such as air speed, vibration frequency, and conveying speed are intuitively adjusted via knobs or buttons. Preset programs (optimal parameters for common grain and bean varieties) are included. Users simply select the program corresponding to the grain or bean type and start the process, eliminating the need for complex adjustments.

From a “tool for increasing farmers’ income” to a “core of production” for businesses, the grain and bean air-screening gravity separator redefines the standard for grain and bean cleaning with its multiple advantages: high efficiency, precision, versatility, economy, and intelligence. Whether farmers seeking to increase profits or businesses committed to quality improvement, choosing our TaoBo grain and bean air-screening gravity separator is a wise move towards efficient production and high-quality development.

Post time: Sep-08-2025