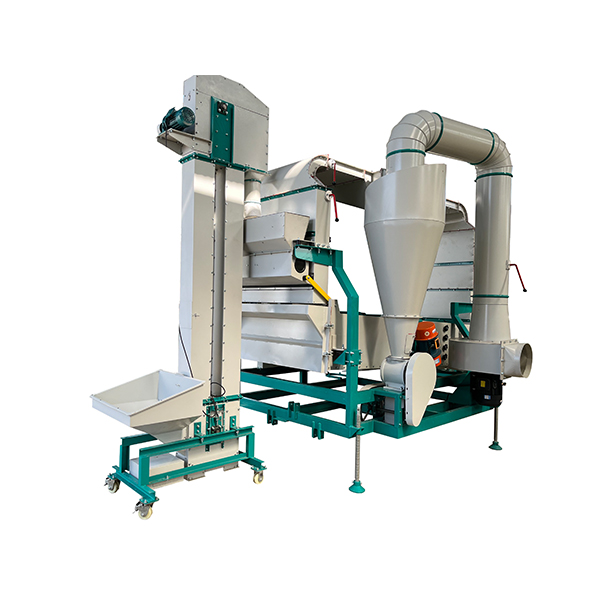

The autumn harvest brings a bountiful harvest of pumpkin seeds, but the accompanying challenges of seed cleaning present a challenge for many farmers. Traditional manual seed cleaning is not only time-consuming and labor-intensive, but also difficult to ensure quality. Impurities often affect the selling price of the seeds. At Taobo, we have developed a wind screen cleaning machine. With its many outstanding advantages, it has become a valuable aid for farmers, resolving this difficult pumpkin seed cleaning problem.

Precise Separation Ensures Pumpkin Seed Quality

The quality of pumpkin seed cleaning directly impacts both quality and economic profitability. Our Taobo wind screen cleaning machine utilizes a dual cleaning process: wind sorting + multi-layer screen screening, achieving precise pumpkin seed separation. The wind system adjusts the air speed based on the weight difference between the pumpkin seeds and impurities (such as rind, dust, and shrunken seeds), quickly removing lightweight impurities. The multi-layer screens with varying apertures precisely select the pumpkin seeds based on their size, selecting plump, standard seeds while simultaneously removing small particles and immature seeds. Pumpkin seeds cleaned by this machine have an impurity content below 1% and a plumpness of over 95%, fully meeting market demand. High-quality pumpkin seeds not only command higher prices but also build a positive market reputation, generating sustainable profits for farmers.

Continuous operation without degradation, consistent cleaning results

Large-scale pumpkin seed processing companies often require 24-hour continuous cleaning operations. Traditional equipment is prone to problems such as wind power degradation and screen wear after prolonged operation, resulting in reduced cleaning performance. The Taobo air screen cleaner utilizes industrial-grade wear-resistant materials and a stable power system. The fan utilizes a high-speed permanent magnet motor, ensuring wind speed fluctuations of no more than 0.2 m/s after 200 hours of continuous operation. The screen is constructed of manganese steel with a surface hardening treatment, increasing wear resistance by three times and providing a service life of over 3,000 hours.

Compared with traditional cleaning methods, the cleaning performance advantages are clear at a glance. The air sieve cleaning machine completely outperforms traditional methods in key cleaning metrics. Take impurity removal rate, for example. Manual cleaning, limited by the naked eye, cannot completely remove fine impurities. Ordinary sieves can only separate large and small impurities by aperture size, leaving them powerless against impurities of similar weight. The pumpkin seed air sieve cleaning machine, however, utilizes a dual process to achieve “complete removal of large and small impurities, and separation of both light and heavy impurities,” ensuring that every pumpkin seed meets “clean, uniform, and high-quality” standards.

The Taobo air screen cleaner, with its precise, stable, and efficient cleaning performance, has redefined the industry standard for pumpkin seed cleaning. Whether it’s small-scale processing on a family farm or large-scale production at a large enterprise, its superior cleaning capabilities provide strong support for improving the quality and efficiency of the pumpkin seed industry, ensuring that every harvest is transformed into tangible value.

Post time: Sep-15-2025