Air screen cleaner with gravity table it can clean sesame, Beans Groundnuts with high performanc, It can remove all the bad beans as well. After cleaning the sesame purity will reach 99%

The core advantage of the air-screen gravity separator for cleaning pumpkin seeds is that it integrates “impurity removal + grading + heavy impurity removal,” making it suitable for the characteristics of pumpkin seeds—flat kernels, thin shells, and various types of impurities—and achieving cleaning efficiency and purity far exceeding that of single-unit equipment.

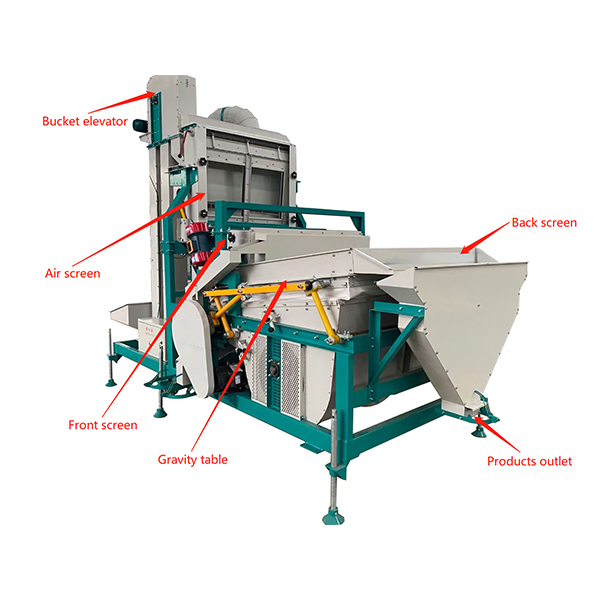

Air screen can remove light impurities such as dust, leaves, some sticks, The vibrating box can remove small impurity. Then gravity table can remove some light impurities such as sticks, shells, insect bitten seeds. the back half screen remove bigger and smaller impurities again. And This machine can separate the stone with different size of the grain/seed, This is the whole flow processing when the cleaner with gravity table working.

I. Core Cleaning Functions (Specifically for Pumpkin Seeds)

Air Separation for Light Impurities: Adjustable airflow separates light impurities such as broken shells, dust, shriveled seeds, and dry grass from pumpkin seeds. Pumpkin seeds have thin shells and low suspension speed; the airflow intensity is adjusted to “support shriveled seeds without blowing away plump seeds,” preventing shell breakage or seed loss.

Sieving for Large/Small Impurities: Multiple layers of screens (with interchangeable apertures) precisely separate impurities of different sizes. The upper screen uses apertures slightly larger than pumpkin seeds (approximately 8-10mm) to remove large impurities such as branches and large stones; the lower screen uses apertures smaller than plump pumpkin seeds (approximately 5-6mm) to remove fine sand, broken seeds, and other small impurities, simultaneously grading the pumpkin seeds by size.

Specific gravity removal: Utilizing the density difference between pumpkin seeds (density approximately 0.8-1.0 g/cm³) and heavy impurities (stones, metal particles, mud lumps, density ≥ 2.5 g/cm³), a tilted vibrating specific gravity platform allows plump pumpkin seeds to move upward with airflow and vibration, while heavy impurities slide down the platform and are discharged. It can also separate “side-by-side stones” that are similar in size to the seeds.

II. Key Parameter Matching (To Avoid Pumpkin Seed Damage or Leakage)

Screen Selection: Prioritize perforated or woven screens (8-10mm/5-6mm double-layer aperture). Use 304 stainless steel for the screen material to prevent sharp edges from scratching the pumpkin seed shells.

Airflow and Vibration Adjustment: Airflow intensity should be 10%-20% lower than when cleaning beans. Control the vibration frequency at 50-70Hz to prevent thin-shelled pumpkin seeds from being blown or cracked.

Processing Capacity Matching: For small-scale processing (1-3 tons per day), select a 1-2 ton/hour model. For large-scale processing (over 5 tons per day), select a 3-5 ton/hour model. Avoid overly large machines that result in insufficient seed retention and incomplete cleaning.

III. Precautions for Use

Uniform Feeding: Pumpkin seeds are prone to clumping, so a uniform feeding device is required to prevent excessively thick local layers of material, which can affect the air separation and screening effects.

Regular Screen Cleaning: Crushed pumpkin seed shells can easily clog the screen. Clean the screen surface every 2-3 hours to prevent clogging and grading failure.

Post-Processing: To improve the gloss of the pumpkin seeds, a small polishing machine (soft brush type) can be used after the cleaner. Avoid hard polishing that could damage the seed shells.

Features

● Easy installation and high performance .

●Larger production capacity : 10-15tons per hour for grains .

●Environmental cyclone duster system to protect clients warehouse .

● This seed cleaner can be used for various materials. Especially sesame, beans , groundnuts .

● The cleaner has low speed non broken elevator, air screen and gravity separating and other functions in one machine.

Advantage

● Easy to operate with high performance.

● High Purity :99% purity especially for cleaning sesame, groundnuts beans

● High quality motor for seeds cleaning machine, high quality Japan bearing.

● 7-15 Ton per hour cleaning capacity for cleaning different seeds and clean grains.

● Non broken low speed bucket elevator without any damage for the seeds and grains.

What is the difference between seed cleaner and seed cleaner with gravity table ?

The structure it is totally different , The seed cleaner gravity table It consists of Bucket Elevator, Air Screen, Vibrating box , Gravity Table and Back Half Screen . But sample seed cleaner consists Bucket Elevator, Dust Collector, Vertical Screen, vibrating box and Sieve grader , Both of them can clean the dust , light impurities and larger impurities and so on from sesame seeds , beans ,pulses and other grains , But the seed cleaner with gravity table can remove the bad seeds , injured seeds and broken seeds as well . normally the seed cleaner as the pre-cleaner in the sesame processing plant , seeds cleaner with gravity table will used with grading machine together for processing sesame ,and groundnuts ,different kind of beans .

Post time: Nov-13-2025