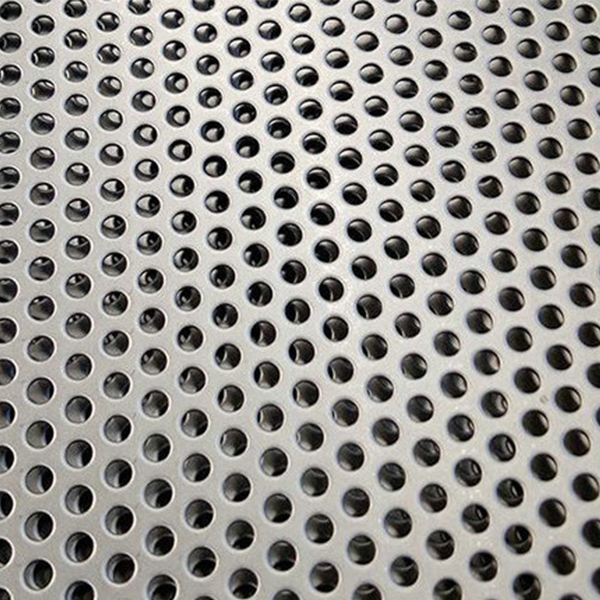

The mesh size of a pneumatic screen cleaner is a key parameter determining the effectiveness of impurity removal and the yield of finished products for beans (such as chickpeas, soybeans, and peas). Its key influence is to achieve precise separation by matching or mismatching the particle size differences between beans and impurities. A mesh size that is too large or too small not only results in impurities remaining and loss of qualified beans, but can also cause mesh clogging and reduced processing efficiency.

1. Impact on “Impurity Removal Efficiency”: Directly Determines Whether Impurities Can Be Accurately Separated

Impurities that need to be removed during bean processing can be categorized by particle size into “large particles” (such as straw segments, large lumps of soil, and irregular shapes) and “small particles.” The screen aperture must be designed for each type of impurity. Aperture deviation can directly lead to separation failure:

1. For “large particles”: Rely on the “upper coarse screen.” If the aperture is too small, impurities will remain, while if it is too large, separation will be ineffective.

Principle: The upper coarse screen intercepts impurities larger than the acceptable beans, allowing the acceptable beans and small impurities to pass through the screen. The vibration of the screen surface pushes the large impurities to the outlet. Impact of Aperture Size:

Too small an aperture (smaller than the maximum acceptable bean size): Large impurities are intercepted, but acceptable beans, larger than the aperture, cannot pass through the coarse screen and are forced to be discharged along with the large impurities. This results in “acceptable beans mixed with impurities.” While the impurity removal rate may appear high (large impurities are intercepted), it actually results in “finished product loss.” Furthermore, large impurities mixed with acceptable beans require secondary sorting after discharge, increasing costs.

Too large an aperture (much larger than the maximum acceptable bean size): Large impurities (such as coarse straw and large clumps of mud) pass through the screen along with acceptable beans and enter the lower screening stage. This results in “large impurities missing from the screen,” potentially mixing into the finished product or clogging subsequent fine screens (e.g., straw entangled in the mesh).

2. For “small impurities”: Rely on the “lower fine screen.” Too large an aperture will retain impurities, while too small an aperture will clog the screen.

Principle: The lower fine screen’s function is to “allow small impurities smaller than acceptable beans to pass through, while intercepting acceptable beans,” achieving “qualified beans from small impurities.” Impact of Aperture Size:

If the aperture is too large (larger than the minimum acceptable bean size), small impurities (such as 5mm pebbles and broken beans) will be trapped along with the acceptable beans and unable to pass through the fine screen. This can result in small impurities being mixed into the finished product, such as stones being bitten during consumption or wear and tear on subsequent equipment (such as mills) during processing.

If the aperture is too small (much smaller than the minimum acceptable bean size), small impurities can pass through without issue. However, fine particles of acceptable beans (such as underdeveloped small beans, which are acceptable but have a particle size close to the lower limit) can be misscreened and discharged with the small impurities. This can lead to the loss of acceptable small beans. Furthermore, if the aperture is too small (e.g., less than 3mm), fine sand and dust can easily clog the screen holes, reducing the screen’s throughput and requiring frequent machine downtime for cleaning. 2. Impact on Finished Bean Quality: Determining the Purity and Specification Consistency of Finished Products

Bean processing (such as food-grade chickpeas and commercial soybeans) requires not only a “free from impurities” but also uniform particle size (i.e., specification consistency). Screen aperture directly determines these two key indicators:

1. Finished Product Purity: Aperture deviations lead to “impurity retention” or “qualified bean loss.”

As mentioned earlier, if the coarse screen aperture is too small, qualified beans will be mixed with large impurities and discarded; if the fine screen aperture is too large, small impurities will be mixed into the finished product. Both will reduce the purity of the finished product. If used in food processing, impurities may not meet food safety standards; if used in seed processing, impurities will affect seed germination rate. 2. Specification consistency: Aperture diameter determines the particle size range of the finished product. Deviations lead to misclassification of the finished product.

The “middle main screen” of the air sieve cleaner is key to controlling the finished product’s specifications. Its aperture directly corresponds to the “target lower limit of the finished product’s particle size”:

A larger aperture on the main screen allows beans smaller than the target size (such as 7mm small chickpeas) to pass through the screen and be mixed into the finished product, resulting in a “mixed” mix of large and small beans in the finished product and failing to meet market demand for “uniform specifications.”

A smaller aperture on the main screen intercepts some beans of the acceptable particle size (for example, 8mm target beans cannot pass through a 7.5mm screen due to clogged screen holes or insufficient vibration). This results in an excessively high proportion of large beans in the finished product. Furthermore, the intercepted beans are discarded along with the large impurities, resulting in waste. III. Impact on Processing Efficiency and Equipment Loss: Improper Aperture Causes Screen Clogging and Increased Energy Consumption

Screen aperture not only affects separation efficiency but also indirectly impacts equipment operating efficiency and service life:

1. Processing Efficiency: Too small an aperture can easily clog, while too large an aperture requires secondary processing.

Too small an aperture: Beans or impurities can easily get stuck in the screen holes (e.g., round beans getting stuck in square holes, fine sand clogging small holes), resulting in reduced screen throughput. Equipment that originally processed 1 ton of beans per hour might drop to 0.5 tons due to clogging, requiring frequent downtime for screen cleaning with a brush or high-pressure air, severely impacting processing progress.

Too large an aperture: Large impurities can escape screening and enter downstream processes (such as fans and conveyor belts), potentially entangled in equipment components (e.g., straw entangled in fan impellers), increasing equipment load and requiring downtime for cleaning, also reducing efficiency. Furthermore, excessive impurities in the finished product require secondary screening, adding additional time and labor costs. 2. Equipment Wear and Tear: Improper Aperture Increases Screen Wear and Motor Load

Too small an aperture and high vibration frequency: The screen must withstand greater material compression and vibration friction (for example, large impurities get stuck in the screen holes and repeatedly rub against the screen edges with vibration). This shortens the life of the screen (usually metal or nylon mesh) and requires frequent replacement (a normal screen lifespan is 3-6 months, but severe blockage may cause breakage within a month).

Overly large an aperture leads to excessive impurities: Small stones and lumps of soil enter downstream equipment (such as elevators and classifiers), exacerbating wear on internal components (e.g., scrapers on elevators scratched by stones, and lumps of soil on classifier drums), increasing equipment maintenance costs.

The aperture of the air screen cleaner has a “global” impact on the screening of impurities in beans. The core of aperture selection is to “precisely match the particle size difference between beans and impurities.” If the aperture is too large, impurities will be screened out and the finished product will be impure. If the aperture is too small, qualified beans will be lost and the screen will be clogged.

Post time: Sep-25-2025