Coffee is the most important cash crop in Tanzania, with more than 40% of the country’s farmers growing coffee and accounting for 39% of the permanent crop area.

Coffee bean cleaning equipment is a key tool to ensure coffee bean quality, improve processing efficiency and meet market standards. Its necessity runs through the entire process from post-harvest processing to final sales.

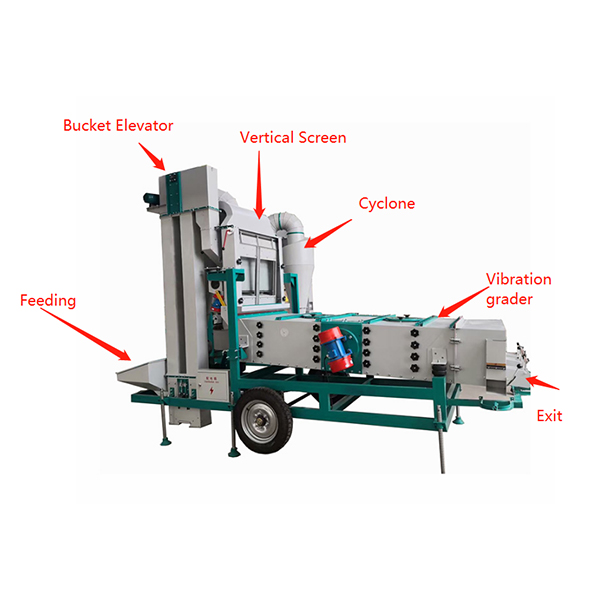

The seed cleaner and grains cleaner it can remove the dust and light impurities by vertical air screen , Then vibrating boxes can remove the big and small impurities , and Grains and seeds can be separated big ,medium and small size by different sieves . and it can remove the stones .

1. Ensure Coffee Bean Quality and Remove Core Impurities

After being harvested from the orchard, coffee beans are often contaminated with numerous impurities that can affect quality and must be cleaned using specialized equipment.

Removing Physical Impurities: Cleaning equipment effectively separates stones, dirt, branches, leaves, and other impurities from the coffee beans, preventing these impurities from causing a burnt odor during subsequent roasting or damaging processing machinery.

Removing Defective Beans: Screening removes impurities such as immature, insect-infested, and moldy beans, directly enhancing the coffee’s flavor purity and reducing negative flavors such as sourness and off-flavors.

2. Improve processing efficiency and reduce labor costs.

Traditional manual cleaning methods are no longer sufficient to meet the scale-up needs of the Tanzanian coffee industry. This equipment can significantly optimize the processing process.

Replacing inefficient labor: Manual sorting of impurities and defective beans is extremely inefficient, with one worker processing less than 100 kilograms per day. A small cleaning device, on the other hand, can process 500-1000 kilograms per day, significantly shortening the processing cycle.

Reducing reliance on labor: Tanzania’s coffee production is primarily based on smallholder farmers, and the processing stage often faces labor shortages. This equipment can reduce the need for temporary workers and stabilize the processing process.

The air filter cleaner is a highly efficient device for cleaning coffee beans. Its core advantage lies in its ability to combine wind power and screening to precisely separate different types of impurities. It also adapts to the physical properties of coffee beans, balancing cleaning effectiveness with quality assurance.

Dual Cleaning for More Thorough Impurity Separation

The air filter cleaner uses a combination of wind power and screening to specifically remove two key impurities from coffee beans, achieving cleaning results far superior to either single method.

Air filter cleaning: Utilizing the differences in specific gravity of different materials, the adjustable air speed removes lightweight impurities (such as leaves, dust, and shell fragments), preventing them from adhering to the surface of the beans or mixing with them.

Sieving filter cleaning: Using multiple layers of screens with varying apertures, heavy impurities (such as stones and dirt) and unqualified beans (such as undersized, unripe beans) are separated by particle size, ensuring a uniform quality of retained beans.

Post time: Oct-24-2025