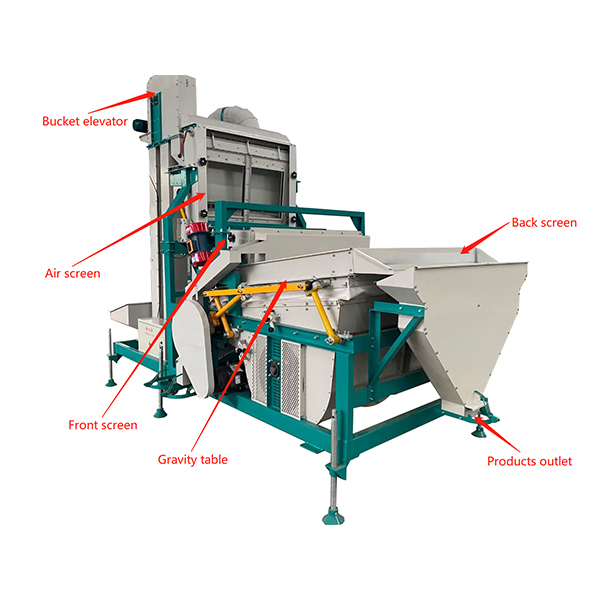

The air-screen gravity separator is a core integrated piece of equipment for cleaning and processing grains and beans. Essentially, it integrates two core functions: “air-screen cleaning” (removing light impurities and grading) and “gravity cleaning” (removing heavy impurities and selecting superior grains). It can complete the entire process from initial cleaning to fine selection of raw materials without requiring the equipment to be disassembled.

Core Working Principle (Two Functions Working Together, Adapted to Mexican Crop Characteristics)

1. Air Screen Cleaning System (Impurity Removal, Grading)

Core Logic: Utilizing the dual action of “air power + screen,” it first separates light impurities (straw, broken leaves, dust) from the raw material, then grades them according to particle size through screens of different apertures (adapting to the different particle size requirements of corn and beans).

Suitable Scenarios: Mexican corn cultivation easily mixes with field straw and weeds; after bean harvest, it contains broken bean husks. The air screen system can quickly complete the initial cleaning, preventing impurities from affecting subsequent processing or storage.

2. Gravity Cleaning System (Further Purification, Selection of High-Quality Particles)

Core Logic: Utilizing the difference between “gravity + airflow,” it separates heavy impurities (pebbles, soil clods, heavy metal particles) and “inferior particles” (shriveled kernels, insect-damaged kernels, empty shells) from the raw material. High-quality particles have a uniform specific gravity and will be smoothly conveyed forward along the screen surface; heavy impurities, due to their excessive specific gravity, settle and separate; inferior particles, due to their light specific gravity, are carried away by the airflow.

The air-screen gravity separator plays a core processing role in the cleaning of grains and beans in Mexico. Its function revolves around the dual needs of Mexican agriculture: “ensuring domestic sales and increasing export efficiency.” It not only solves the problems of impurities and uneven quality after local crop harvest, but also meets the access standards of the international market.

1. One-stop cleaning and grading for improved processing efficiency: After harvesting, crops such as corn and beans in Mexico are generally mixed with impurities such as straw, stones, and shriveled kernels, with significant differences in kernel size. Traditional single-stage air sieves can only remove light impurities and perform grading, while single-stage gravity separators require pre-cleaning before operation. Both processes require material transfer, which is time-consuming and labor-intensive. The air-screen gravity separator integrates “air sieve pre-cleaning + grading + gravity selection” functions. Impurity removal, size grading, and quality screening are completed simultaneously with a single feed of raw materials, increasing efficiency by 30%-50% compared to traditional combined equipment. It is suitable for the batch processing needs of large-scale farms and processing enterprises in Mexico (such as processing during the concentrated harvest season in the central highland corn-producing areas).

2. Improved product quality to meet export standards: Mexico is the world’s fourth-largest exporter of red beans, and also has significant export demand for corn, avocados, and other products. The international market has strict requirements for the impurity content (usually ≤0.5%) and kernel uniformity of agricultural products. This equipment uses gravity separation to precisely remove heavy impurities such as stones and heavy metal particles, as well as inferior products like insect-damaged and shriveled beans. It increases the screening rate of high-quality beans to over 98% and controls the impurity content to within 0.3%, helping local businesses overcome trade barriers and increase the added value of their export products. For example, cleaned red beans are plump and uniform, and can fetch a price 10%-15% higher than uncleaned products.

3. Reduced Losses and Costs, Adapting to the Needs of Small and Medium-Sized Farmers: Mexican agriculture comprises a large number of small and medium-sized farmers and cooperatives with limited budgets for equipment investment and difficulty affording the maintenance costs of complex equipment. The multi-functional air-screen gravity separator is compatible with various crops such as corn, beans, red beans, and chickpeas, eliminating the need to purchase multiple units and reducing initial investment. Simultaneously, its integrated design reduces energy consumption (25%-30% lower than single-unit combinations), and its modular structure facilitates disassembly and maintenance, allowing farmers to operate it without specialized technical personnel, perfectly suited to local rural production conditions. Furthermore, the equipment loss rate can be controlled below 2%, far lower than traditional manual screening (loss rate approximately 8%-10%), reducing crop waste.

4. Adapting to Regional Environments, Ensuring Processing Continuity: In the arid regions of northern Mexico, corn and beans are prone to soil contamination with stones, while in the rainy regions of the south, shriveled and moldy kernels are common. Additionally, some remote areas suffer from unstable power supply issues. The equipment’s wind power, screen aperture, and specific gravity screen angle are all flexibly adjustable, allowing for targeted treatment of crop impurities in different production areas. It also supports diesel generator power, preventing processing interruptions due to power outages and ensuring continuous operation during the harvest season.

5. Facilitating Industrial Chain Upgrading and Promoting Standardized Production: Previously, some small and medium-sized farmers in Mexico relied on manual screening, resulting in inconsistent quality and difficulty in achieving large-scale, standardized supply. The widespread adoption of air-screen specific gravity separators can promote the transformation of local grain and bean processing from “extensive” to “intensive” methods, helping processing enterprises establish stable quality standards, attracting more international buyers, and thereby driving the optimization of planting structures in production areas (such as guiding farmers to plant high-quality varieties more suitable for export), forming a virtuous cycle of “planting-processing-export”.

Post time: Dec-12-2025