The air-screen gravity separator is a composite machine that combines air separation, screening, and gravity separation. Compared with ordinary separators that rely solely on air separation or screening, its core advantages are higher cleaning accuracy, wider impurity removal range, stronger adaptability, and the ability to improve the value of finished products and operational efficiency. It is especially suitable for scenarios with high quality requirements, such as seed selection and grain grading.

Step 1: Air Separation to Remove Light Impurities – Separating Light Impurities by Utilizing Differences in Suspension Velocity

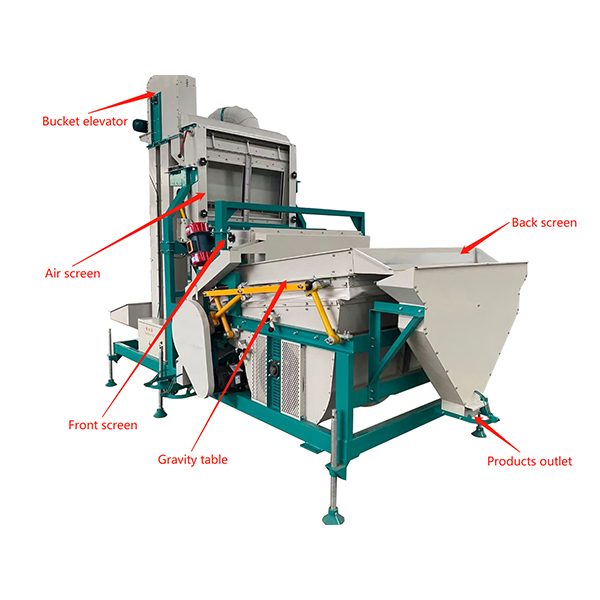

This is the pre-cleaning stage, primarily composed of a centrifugal fan, air duct, and settling chamber. The fan generates a precisely adjustable directional airflow, with the airflow velocity matched to the suspension velocity threshold of the material to be processed.

When raw grain (including straw, dust, empty husks, shriveled grains, etc.) enters the air separation channel, light impurities with low suspension velocity (dust, straw fragments, empty husks) are blown up by the airflow and collected and discharged through the settling chamber; heavy materials with high suspension velocity, such as full grains, sand, gravel, and clods of soil, cannot be carried by the airflow and fall down the channel into the next screening stage;

Step Two: Screening by Size – Separating impurities of different sizes using differences in particle size/shape

This is the intermediate grading stage, the core of which is a multi-layer vibrating screen body (equipped with screens of different specifications), a vibrating motor, and an eccentric shaft. The screen body is driven by the vibrating motor to perform reciprocating linear/circular vibration. The screens are multi-layered grading designs, with each layer having different screen aperture sizes, arranged in a “larger at the top, smaller at the bottom” pattern.

When the material from the air separation falls onto the upper screen, large impurities larger than the screen openings (large clods of soil, straw fragments, large stones) cannot pass through and are discharged from the outlet along the screen surface. Qualified grains of the correct size, plus small impurities smaller than the screen openings (small sand, gravel, broken grains, shriveled grains), pass through the upper screen and fall onto the lower screen. The lower screen openings match the minimum size of the qualified grains; small impurities smaller than the screen openings pass through the screen and are collected, while qualified grains of the correct size remain on the screen surface and enter the core gravity separation stage via a guide plate.

Step 3: Gravity Separation for Quality Determination — Separating density-specific gravity impurities using density differences (core process)

This is the core difference between the air-screen gravity separator and ordinary separators. It targets adjacent impurities that cannot be separated in the first two steps (such as adjacent stones, moldy grains, insect-damaged grains, and shriveled grains that are similar in size to the kernels). These impurities are similar in size to qualified kernels, but their density and specific gravity differ significantly. The core process consists of a gravity platform, a blower (bottom blower), a vibration mechanism, and an angle adjustment device; it is also the most complex step.

Core Advantages Analysis

1. More Comprehensive Cleaning Principle, More Thorough Impurity Removal

Ordinary Cleaners: Primarily based on single air separation or sieving, they can only separate impurities with large differences in size and weight from the material, such as straw, clods, and broken particles. They are ineffective at separating impurities with small differences in specific gravity, such as adjacent stones, moldy particles, and insect-damaged particles. The impurity removal rate is usually below 90%, and imperfect particles are easily mixed in.

Air-Screen Gravity Cleaner: Integrates a three-layer separation logic—first, air separation removes light impurities (dust, straw); then, sieving removes impurities of different sizes (stones, broken particles); finally, a gravity plate separates particles according to density, with heavier particles (full grains) sinking and rising, while lighter impurities (empty grains, moldy grains) float and are discharged. This removes over 90% of specific gravity impurities, achieving a total impurity removal rate of over 98.5%. It can also separate adjacent impurities with similar specific gravities, significantly improving purity.

2. Higher Finished Product Quality and Significantly Enhanced Value: Ordinary grain cleaners cannot accurately separate gravity-related impurities, resulting in residual imperfect and moldy grains in the finished product. This affects storage stability and product grade, and also makes it difficult to guarantee seed germination rates.

Air-screen gravity separators can accurately grade grains, improving plumpness and uniformity. Seeds processed from these separators have higher germination rates, and graded grains meet high-grade purchasing standards, facilitating premium sales. They are particularly suitable for the refined processing of cash crops such as beans, sesame, and coffee beans.

3. Multi-functional, Greater Adaptability and Flexibility: Ordinary grain cleaners are mostly designed for single crops or fixed impurity types. Changing materials requires frequent adjustments or component replacements, resulting in a narrow range of applications.

Air-screen gravity separators, by adjusting airflow, screen size, and the vibration frequency and angle of the gravity table, can process multiple crops such as wheat, corn, beans, and oilseeds. Variety switching can be achieved without significant modifications, making them suitable for various scenarios such as large, medium, and small grain depots, seed processing plants, and cooperatives, reducing equipment investment costs.

What are the applicable scenarios for air-screen gravity separators?

Field crop seed selection: For conventional seeds such as wheat, corn, rice, sorghum, and millet, it removes chaff, moldy, insect-damaged, and conglomerate grains, while separating grains of different plumpness for grading, improving seed germination rate and seedling uniformity.

Oil crop seed selection: For rapeseed, peanut, sesame, and sunflower seeds, it removes empty shells, shriveled grains, and impurities, ensuring optimal thousand-grain weight and germination vigor.

Vegetable/Fruit seed selection: For small seeds such as cabbage, radish, tomato, pepper, and watermelon, it removes dust, broken seeds, and shriveled seeds through precise adjustment of airflow and screen, improving seed purity.

Post time: Feb-02-2026