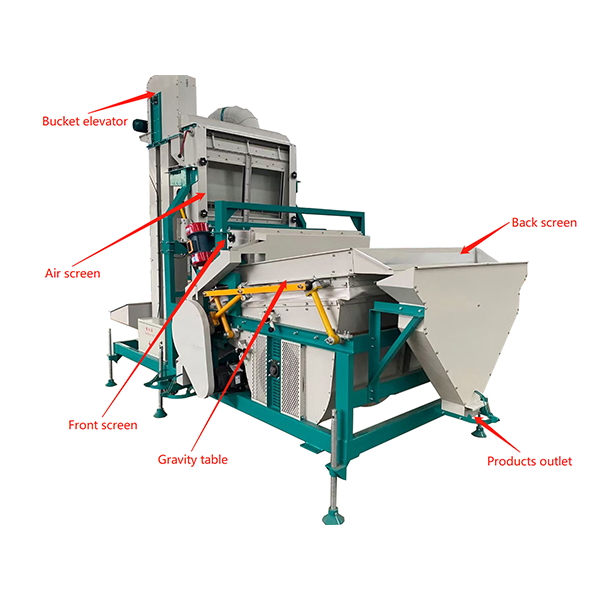

The Air-screen Cleaner with Gravity Table consists of ultra low speed, no broken elevator, vertical air screen, cyclone dedusting system, large proportion platform, vibrating and grading screen. It can remove dust, chaff, shell and other light impurities. It can also remove the blighted seed, budding seed, damaged seed (by insect), rotten seed, deteriorated seed, moldy seed, non-viable seed, seed with black powder sick. After the large and small impurities have removed, the finished product can be divided into best, medium and small particles.

The air screen gravity cleaner cleans soybeans, combining the dual functions of “screening and impurity removal” and “gravity sorting”. It can not only remove large and small impurities in the soybeans, but also separate out poor quality soybeans such as hollow and worm-eaten grains. The cleaning effect is better than that of ordinary air screen machines.

I. Core Cleaning Logic and Process

Step 1: Pre-screening (Size Separation): The vibrating screen at the front of the machine filters out large impurities (such as bean stalks, weeds, clods of soil, and broken pods) and small impurities (such as fine sand, bean fragments, and insect eggs) from the soybeans.

Upper Screen: Use a screen with a pore size slightly larger than that of normal soybeans (usually 4.5-5mm). This allows the soybeans and small impurities to pass through, while retaining large impurities.

Lower Screen: Use a screen with a pore size slightly smaller than that of normal soybeans (usually 3.5-4mm). This allows small impurities to pass through, while the soybeans remain on the screen surface for the next step.

Step 2: Gravity Sorting (Quality Separation): This is the core process of the air sieve gravity machine. It uses a combination of “airflow + inclined screen surface” to separate different weight components within the soybeans:

Normal soybeans: Fuller, denser beans overcome airflow resistance, slide downward along the inclined screen surface, and enter the “high-quality bean collection channel.” Light impurities and inferior beans: hollow, worm-eaten, and moldy beans have a low density and will be blown up by the airflow or move upward with the slight vibration of the screen surface and enter the “inferior bean/light impurity discharge channel”; at the same time, the remaining light impurities (such as dust and fluff) will be directly sucked away by the fan.

This machine can replace gravity separator, reduce the load of gravity table and increase production further.Environmental cyclone duster system and without a lot of dust leakage.The front sieve can remove small impurities, which can reduce the load of gravity table and blockage of small particles.For the processing of wheat, rice, corn, soybean, sorghum and other commodity grains, productivity can reach 20t/h, and can remove more than 90% kinds of light impurities from grain.

While conventional equipment can only address a single separation requirement, the air screen gravity separator addresses both simultaneously, covering the entire cleaning scenario. It offers a wider range of applications: It adapts to the characteristics of a wide range of materials. From a processing perspective and in terms of long-term use, this equipment can significantly improve efficiency and reduce hidden costs.

Post time: Oct-22-2025