Major Legume Varieties Grown in Peru

Peruvian agriculture is influenced by the Andean mountain range and tropical/subtropical climate. Legume cultivation combines local varieties with internationally traded ones. Major legumes include:

Lima Bean (also known as Quinoa Bean): This is one of Peru’s signature beans, available in large and small varieties. Adapted to the climate of Peru’s coastal irrigated areas and mountainous regions, it is an important part of local traditional cuisine and exports, often used in soups, stews, or processed into bean puree.

Black Bean: Widely grown in the tropical and subtropical regions of northern and central Peru, it is a staple legume for domestic consumption and is also exported to North America and Europe. It is suitable for making sauces, salads, and as a main dish accompaniment.

Soybean: With the development of Peruvian agricultural industrialization, soybean cultivation has expanded annually, mainly concentrated in large-scale farms on the coastal plains. Its main uses are oil extraction, processing into soy products, and animal feed. Some products are exported to neighboring Asian and Latin American countries.

Kidney beans, including varieties such as red and white kidney beans, are grown in the mid-altitude areas of the Andes Mountains. They are a crop used by local farmers for both self-spent seeds and commercial cultivation, and are mostly used in traditional dishes and processed bean products.

Quinoa originated in the mid-to-high altitude mountainous regions of the Andes Mountains in South America, including Colombia, Ecuador, and Peru. Peru is the world’s largest quinoa producer. Here is a detailed overview of quinoa cultivation in Peru:

Planting Area and Yield: The planting area of quinoa in Peru has been increasing, from approximately 35,000 hectares in 2000 to about 200,000 hectares in 2016, with an annual yield of approximately 100,000 tons. Since the Peruvian government implemented the “Quinoa Development Plan” in 2011, quinoa production has increased by approximately 30%.

Planting Areas: Quinoa thrives best in high-altitude or mountainous regions at elevations of 3,000-4,000 meters. Therefore, quinoa cultivation in Peru is mainly concentrated in the high-altitude areas of the Andes Mountains, such as the Puno region, which is one of the main quinoa producing areas.

Varieties: Peruvian agricultural research institutions have developed various quinoa varieties suitable for different altitudes and climatic conditions to improve yield and quality. Among them, Purico quinoa is favored by growers due to its high protein content and strong resistance to adverse conditions.

Varieties: Cultivation Techniques: Peru has continuously improved its quinoa cultivation techniques, employing precision seeding to accurately control seeding rate and depth, thereby increasing germination rate and yield. Irrigation methods primarily utilize sprinkler or drip irrigation, and integrated pest management combining agricultural, biological, and chemical control measures is employed to manage pests and diseases.

Industry Model: Approximately 200,000 farmers in Peru are involved in quinoa cultivation, with about 10% selling their products through cooperatives. These cooperatives help farmers increase their income while also providing consumers with high-quality products.

Export Situation: Peru is the world’s largest exporter of quinoa, accounting for over 60% of the global quinoa export market. In 2019, Peruvian quinoa exports reached approximately US$400 million, with a volume of about 60,000 tons. The main export markets are the United States and the European Union, accounting for approximately 40% and 30% of the export share, respectively.

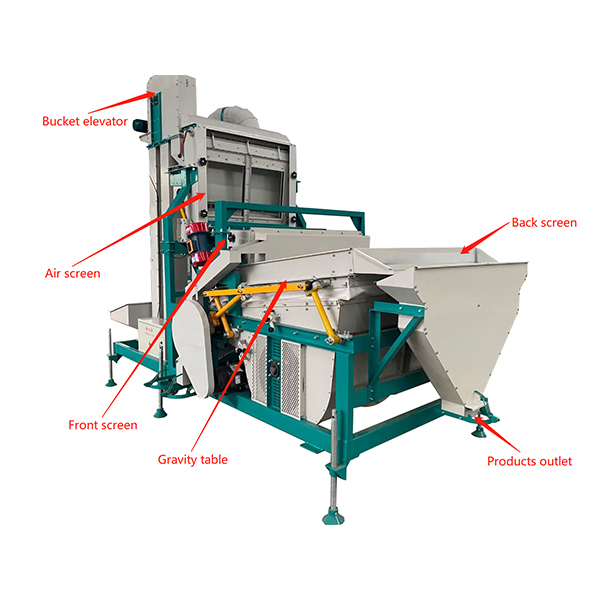

The air-screen gravity separator is a composite cleaning device integrating air separation, screening, and gravity separation. Compared to a single gravity separator, it achieves integrated operation of “light impurity separation → particle size classification → heavy impurity + plumpness separation,” making it a core piece of equipment for the large-scale processing of granular materials such as grains, beans, and quinoa. It is particularly suitable for the cleaning needs of quinoa, lima beans, and chickpeas in the Peruvian Andes Mountains.

I. Core Working Principle (Three-Process Linkage) The core logic of the air-screen gravity separator is “first separate by weight, then by size, and finally by quality.” These three processes are performed sequentially without the need for separate material transfer. The specific process is as follows: Air Separation Pretreatment: After light impurities are removed, the material enters the equipment and first passes through the airflow zone of the built-in fan. Low-density light impurities such as straw, weed seeds, empty grains, and dust are blown into the waste collection port by the airflow; plump grains, due to their high density, overcome airflow resistance and fall into the screening zone below. Suitable for Peruvian environments: Designed for high-altitude, low-pressure environments, the fan power can be manually/automatically adjusted to avoid insufficient airflow penetration due to altitude, ensuring thorough separation of light weed seeds from quinoa and beans in mountainous areas.

Screening process: Material is graded by particle size and undergoes preliminary impurity removal. After air separation, the material falls onto a multi-layer vibrating screen. The screen aperture can be customized according to the material type (e.g., 1-2mm for quinoa, 2.5-3mm for chickpeas, 3-5mm for lima beans).

Small impurities smaller than the screen aperture (such as mud, sand, and fragments) will pass through and be discharged; larger particles (such as stones and large grass stalks) will be intercepted by the screen and discharged from the end of the screen surface; material meeting the particle size requirements will pass through the screen and proceed to the next gravity separation process.

Core advantages: Compared to a single gravity separator, pre-screening to remove large and small impurities reduces the load on the gravity separation zone and improves the final separation accuracy.

Gravity sorting: Materials are graded by density and heavy impurities are removed. The sieved material is evenly spread on a vibrating gravity screen bed. A controllable airflow beneath the screen bed forms an “air cushion” to support the material.

High-density, plump kernels: penetrate the air cushion, vibrate close to the screen bed, and slide along the inclined screen surface towards the high-quality discharge port.

Medium-density, lower-grade kernels: remain suspended in the middle layer of the air cushion and fall into the medium-quality discharge port (suitable for domestic processing).

High-density, heavy impurities (such as small stones and lumps of mud): heavier than plump kernels, remain at the front of the screen bed and are discharged from the heavy impurities discharge port.

Supplement: By adjusting the screen bed vibration frequency, airflow intensity, and screen bed inclination angle, the density differences of different materials can be precisely accommodated, such as distinguishing between plump and insect-damaged chickpeas.

Grading and Screening for Premium Prices

Grading sieves can classify beans based on their size and plumpness, for example, dividing lima beans into large, medium, and small grades. Different grades of beans have significantly different market prices—large, plump lima beans can fetch 15%-20% higher export prices than ungraded beans. Grading helps Peruvian exporters access high-end markets (such as the North American organic food market and European supermarket channels).

Ensuring Food Safety and Meeting Importer Standards

Major export markets for Peruvian beans (the US, EU, and China) have strict standards regarding impurities, pesticide residues, and foreign matter contamination in agricultural products. Destoners in cleaning equipment remove hard impurities such as sand and gravel, preventing equipment wear during processing; color sorters remove moldy and discolored beans, reducing the risk of harmful substances such as aflatoxin, helping Peruvian beans pass the inspection and quarantine of importing countries.

Reducing processing losses and improving supply chain efficiency: For large-scale soybean product processing plants (such as soybean oil mills and black bean sauce factories), cleaning equipment can achieve continuous and automated operations, increasing efficiency by more than 10 times compared to manual screening, while reducing soybean breakage and waste during manual screening. Furthermore, pre-treated soybeans have lower impurity content, resulting in lower energy consumption for subsequent washing, cooking, and grinding processes, further reducing processing costs.

Post time: Dec-15-2025