Mung beans: Mung beans are one of Uzbekistan’s important legume crops, with production areas mainly divided into five major regions. The northeastern region produces mainly small and medium-sized mung beans, suitable for sprouting; mung beans produced around Tashkent include small, medium, and large beans, suitable for commercial production. Uzbekistan exports a large quantity of mung beans to countries such as China.

Cultivation: Major production areas are concentrated in Namangan, Samarkand, Surkhandarya, Tashkent, Fergana, and Khorezm regions. Irrigation is mostly via irrigation ditches, with some areas experiencing increased mechanization. The western region primarily produces small-sized sprouted beans (accounting for approximately 55% of exports), while the eastern region mainly produces commercial beans. In recent years, the planting area has continued to expand due to export demand, and farmers are increasingly willing to switch to this crop due to its time-saving and stable returns.

Production: Data from the Uzbekistan Statistical Service in 2024 shows a production of 384,000 tons, with exports reaching 123,000 tons (112,000 tons to China). The previous output for 2023/24 was about 150,000-160,000 tons, and the output for 2024/25 is expected to be 180,000-200,000 tons, with an average yield of about 180 jin per mu, and up to 270 jin per mu in advantageous areas.

Chickpeas: Also a widely cultivated and exported legume in Uzbekistan. Rich in nutrients, chickpeas play an important role in the Uzbek diet and are also used for processing and export.

Cultivation: As a drought-resistant, high-protein traditional crop, chickpeas are highly adaptable and tolerant of poor soil, making them a good preceding crop for grains. They are mainly distributed in areas with dryland farming conditions, such as Samarkand and Kashkadarya, and are often cultivated using a combination of traditional methods and drought-resistant varieties.

Yield Performance: Data shows that in 2023, Uzbekistan’s chickpea production was approximately 14,300 tons, with a harvested area of 5,350 hectares and a yield of approximately 2,667 kg/hectare. Production has shown a steady upward trend in recent years, driven by domestic food demand and processing exports, leading to a slight expansion in the planting area.

Kidney beans: Including varieties such as white kidney beans and purple-spotted kidney beans, they are cultivated on a certain scale in Uzbekistan. These beans are mainly used for food processing or export to meet domestic and international market demands. For example, some companies in Samarkand are engaged in the production and export of high-quality red beans.

Cultivation situation: The main producing areas include Samarkand, Tashkent, and Fergana, with most cultivation done by small and medium-sized farmers. Some companies are engaged in the large-scale production and export of varieties such as red beans, and the cultivation model takes into account both food processing and export market demands.

Production performance: The official total production of kidney beans is not disclosed separately. FAO data shows that in 2023, Uzbekistan’s bean production (including kidney bean-related categories) was approximately 4,975 tons. The overall scale is smaller than that of mung beans and chickpeas, and production is mainly regional and order-based, with export volume fluctuating with the international market.

The cleaning process for mung beans and chickpeas in Uzbekistan mainly involves a multi-stage combination of “primary cleaning – air sieving – gravity destoning – color sorting – polishing/magnetic separation” to meet the high-cleanliness requirements of its export-oriented industry.

Core Cleaning Equipment and Application Scenarios

1. Primary Cleaning Screen

Function: Performs the first coarse cleaning, efficiently removing low-density and large-volume impurities such as straw, large debris, dust, and empty shells, protecting subsequent equipment. It is a standard entry-level component of large-scale production lines.

Suitable for: High-impurity scenarios after harvesting mung beans and chickpeas. Single-machine processing capacity: 1–15 tons/hour. Can quickly improve raw material purity to over 85%.

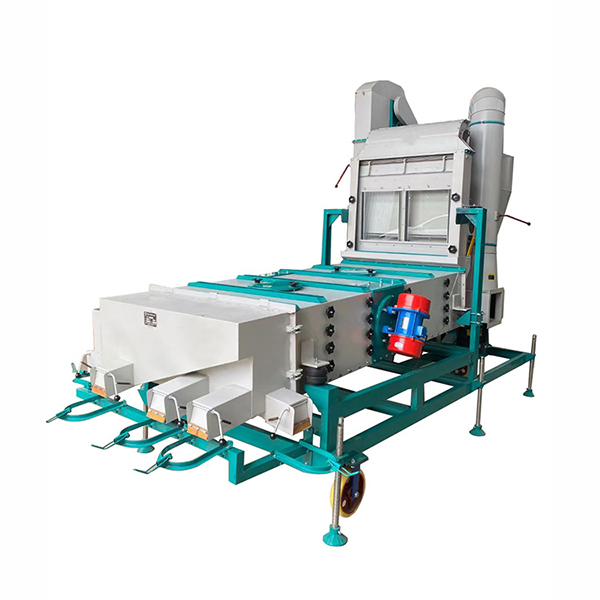

2. Air Screen Cleaner

Function: Integrates air separation and vibrating screen grading, separating small impurities, broken grains, and shriveled grains according to particle size and specific gravity. Simultaneously, it removes light impurities through airflow adjustment. It is a core piece of equipment for improving purity.

Suitable for: Mung bean sorting (small/medium/large), chickpea grading. Customizable screen mesh size to adapt to different production areas and varieties. Purity can reach 95%–98%.

3. Gravity Analyzer & Destoner

Function: Utilizing the density difference between the material and stones/clods of soil, this machine separates high-density impurities under vibration and airflow, solving the problem of adjacent stones that are difficult to remove with air screens.

Suitable for: Soils with high impurity levels in irrigated areas of Uzbekistan; suitable for mung beans and chickpeas; destoning rate ≥99%, ensuring the finished product is free of hard impurities.

Photoelectric Color Sorter (CCD/AI Vision)

Function: Identifies discolored, insect-damaged, moldy, and diseased grains through high-speed imaging, accurately removing minute defects; crucial for export-grade product quality.

Suitable for: Mung bean sprouts/commercial beans, food-grade chickpea processing; can memorize 99 material parameters; one-click variety switching; color sorting accuracy up to 0.01mm; finished product qualification rate ≥99.8%.

Post time: Jan-17-2026