Air-screen cleaners and magnetic separators are complementary core equipment in the soybean cleaning process, working together to purify soybeans by targeting different types of impurities.

I. Air Screen Cleaner (Core Cleaning Equipment, Handling “Non-magnetic, Density/Size Difference” Impurities)

Its core function is to separate impurities from soybeans that differ in “air resistance (density)” or “particle size.” It is the “first and main process” in soybean cleaning, handling over 80% of the impurities.

Screening Function (Grading via Screen): Targets impurities “different in size from soybeans,” such as:

Large Impurities: Soybean stalks, pod shells, broken branches, stones (large particles), weeds;

Small Impurities: Soil dust, fine sand, broken soybean fragments, shriveled soybeans (smaller than normal soybeans).

Principle: The screen has a fixed aperture (matching the size of normal soybean particles). When soybeans pass through the screen, small impurities leak through the apertures, while large impurities are intercepted, achieving “size-based cleaning.”

Air separation (separation by airflow): Targets light impurities with a density different from soybeans, such as:

Light impurities: pod fragments, weed seeds, shriveled soybeans, dust, and fuzz.

Principle: The fan inside the equipment generates a stable airflow. Soybeans (high density) settle quickly in the airflow and fall into the discharge port; light impurities (low density) are carried away by the airflow and enter the impurity collection bag, preventing “mixing of light impurities with soybeans”.

Supplement: In soybean processing, air-screen cleaning machines typically first remove light impurities through air separation, and then screen to remove impurities of different sizes, simultaneously solving the three major problems of “dirt, impurities, and shriveled soybeans”.

After harvesting beans, a variety of impurities are mixed in. These impurities can affect the storage and processing quality of beans, as well as the safe operation of subsequent cleaning and deep processing equipment. Targeted removal is necessary.

Organic Impurities: These impurities are of the same origin as beans or belong to field plant matter and are the most easily mixed in during harvesting.

Plant Residue: Bean stalk fragments, pod shells, leaves, vines, weed stems, etc. These impurities are relatively large and easily clog the sieves of cleaning equipment. They also increase the respiration heat of beans during storage, leading to mold growth.

Shriveled and Broken Beans: Poorly developed, shriveled beans, and bean fragments crushed during harvesting or transportation. These impurities have no processing value and lower the overall grade of the beans.

Weed Seeds: Seeds of weeds growing in the field (such as quinoa seeds, barnyard grass seeds, etc.). Some weed seeds are similar in size to bean seeds. If not removed, they will affect the purity of the beans and the quality of sowing (for beans intended for seed production). Inorganic Impurities: These impurities are mostly hard particles from the field soil, which can severely abrade processing equipment and must be thoroughly removed.

Granite: Clods of soil, sand, small stones, and clods of earth. These impurities have high density and differ significantly in size and density from the beans. They can be separated using the sieving and air separation functions of an air separator.

Mud and Dust: Soil powder adhering to or mixed with the bean grains can contaminate the appearance of the beans and affect the cleanliness of processed products (such as bean flour and bean products).

Special Impurities: These impurities have complex origins and pose a greater threat to equipment and product safety, requiring specialized equipment for removal.

Magnetic Metal Impurities: Iron filings from agricultural machinery wear, iron nails/wires left in the field, and metal fragments mixed in during storage or transportation. These impurities can scratch the core components of oil presses and mills and must be removed using a magnetic separator.

Non-magnetic hard impurities, such as glass shards, plastic fragments, and pebbles (oversized particles), can be partially separated by screening, while others require further removal using a gravity separator.

A magnetic separator, or simply a magnetic separator, is a device that removes soil using magnetic force, primarily used for removing soil from grain.

The iron in soil is not free, elemental iron, but rather iron-containing compounds. Many iron compounds are ferromagnetic, giving soil a certain degree of ferromagnetism. Therefore, the magnetic separator removes soil clods and impurities based on this magnetic property. Since soil’s ferromagnetism is very weak, ordinary magnets have difficulty exerting a significant attraction on it. Firstly, the magnetic separator must utilize a specialized structure to further strengthen its magnetic force. Secondly, it must effectively utilize this weak attraction, amplifying its effect with minimal effort to ensure no soil clods escape.

When the magnetic separator is working, the material moves along a conveyor belt. As the belt rotates around the magnetic roller, the material undergoes free fall in a parabolic trajectory. During this process, soil clods are attracted by the strong magnet, their trajectory changes, and they are separated by the separator.

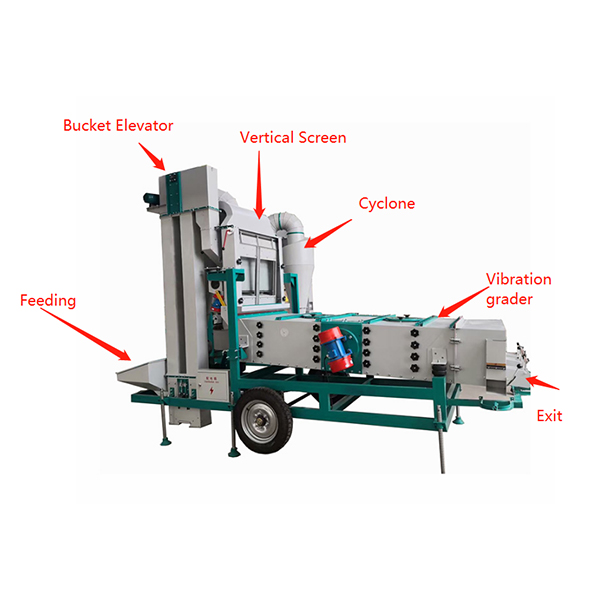

Material is fed into the feeding hopper, then through the elevator and T-junction into the grain bin. It is then dispersed evenly on the conveyor belt by the loose grain. Under the transport of the conveyor belt, the material passes through two rows of filter magnets and magnetic rollers and is then flattened and scattered (to remove strongly magnetic iron impurities from the material and prevent iron impurities from contacting the magnetic rollers and damaging the conveyor belt), forming a flat surface. Since the soil particles contain ferromagnetic substances and are magnetic, their trajectory will change after passing through the magnetic rollers. Therefore, the material can be separated from the soil particles by the diversion plate and finally enter the grain outlet and soil outlet of the grain bin respectively.

Post time: Dec-17-2025