The efficiency of a seed cleaning machine (usually measured by indicators such as the amount of seeds processed per unit time and the cleaning quality compliance rate) is affected by many factors, including the design parameters of the equipment itself, as well as the material characteristics and operating conditions. These factors can be divided into the following categories:

1、Equipment structure and parameters

The design and operating parameters of the core components of the equipment are the basis for affecting efficiency, mainly including

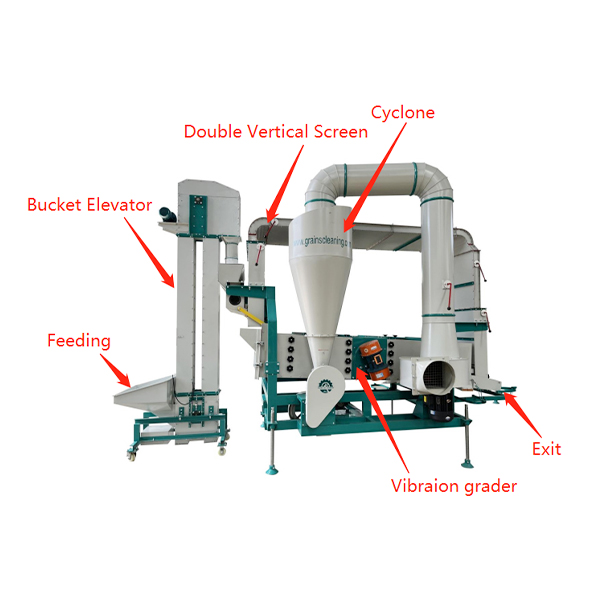

(1)Cleaning mechanism type and configuration: The processing efficiency of mechanisms with different cleaning principles (such as screening, air separation, gravity, color sorting, etc.) varies significantly.For example, the air separator relies on air velocity to separate light impurities. If the fan power is insufficient or the air duct design is unreasonable (such as uneven wind speed distribution), the impurities will not be separated completely, and repeated processing will be required, which will reduce efficiency.

(2)Drive and Speed Control System:Parameters such as the screen surface vibration frequency and amplitude, or the specific gravity table’s tilt angle and vibration intensity, must be matched to seed characteristics (such as specific gravity and coefficient of friction). Improper parameter settings will extend cleaning time and reduce hourly processing capacity.

(3)Equipment Automation:Separators equipped with automatic feeding, automatic impurity removal, and fault alarms can reduce manual intervention (such as frequent machine stops to clean impurities and adjust feed rates), resulting in higher efficiency for continuous operation. Manually controlled equipment, on the other hand, is prone to operational delays, leading to fluctuating efficiency.

2、Physical properties of seeds and impurities

The properties of the processed materials directly affect the difficulty and efficiency of cleaning, mainly including:

(1)The degree of difference between seeds and impurities:The core of cleaning is to exploit the differences in physical properties (particle size, specific gravity, shape, density, surface smoothness, etc.) between seeds and impurities. If the differences are significant, separation is easier and more efficient. If the differences are smaller, more sophisticated equipment or multiple treatments are required, resulting in lower efficiency.

(2)Drive Initial seed condition:Moisture content: Seeds with excessive moisture content (e.g., over 15%) can cause seeds to stick together, clog the sieve, or become difficult to remove during air separation due to their increased weight, reducing cleaning efficiency. Low moisture content can cause seeds to become fragile, potentially generating new impurities and increasing processing load.

3、Operation and debugging factors

Even if the equipment and material conditions are fixed, the operation method will significantly affect the efficiency:

Feed rate control:The feed rate must match the equipment’s rated processing capacity. Parameter Adjustment Precision:Operators must precisely adjust parameters such as mesh size, air speed, and vibration frequency based on seed type and impurity characteristics.

The efficiency of a seed cleaning machine is a function of equipment performance, material characteristics, operator skill, and environmental conditions. In practice, achieving a balance between efficient and high-quality cleaning requires optimizing equipment parameters, precisely matching feed rates, ensuring effective maintenance, and dynamically adjusting operating methods based on seed characteristics.

Post time: Aug-06-2025