Nigeria is an important country in the global production and export of sesame. Its sesame cultivation is centered in the arid northern region. Sesame sorting machines play an irreplaceable role in improving sesame quality and ensuring export competitiveness.

I. Core Characteristics of Sesame Cultivation in Nigeria

1. Geographic Distribution and Climate Adaptability

Sesame cultivation in Nigeria is concentrated in 12 northern states, including Benue, Bauchi, Plateau, Nasarawa, and Borno. These regions fall within the Sahelian climate zone, with annual rainfall of 400-800 mm and a dry season lasting 8-9 months, making them ideal for sesame, a drought-tolerant crop with a short growing season (maturity takes 90-150 days). For example, Benue State’s sandy soil and abundant sunshine make it one of the regions with the highest sesame yields in the country.

2. Production Scale and Export Status

Yields fluctuate significantly: total production in 2020 was 490,000 tons, reaching a historical peak of 995,000 tons in 2012. However, due to factors such as drought and varietal degradation, production has declined in recent years. Export-driven Economy: Sesame is Nigeria’s second-largest agricultural export (after cashew nuts), with exports reaching 139.85 billion naira (approximately US$320 million) in 2022, accounting for 23.34% of total agricultural exports. China is the largest importer (accounting for over 60% of exports), with other destinations including Japan, Turkey, and the European Union.

3. Cultivation Patterns and Challenges

Smallholder Farming: 90% of sesame is cultivated by smallholder farmers, each with an average planting area of 0.5-2 hectares. They use traditional farming methods and lack irrigation and improved varieties.

High Production Costs: Expensive fertilizers (accounting for 35% of cultivation costs) and poor transportation infrastructure (transportation costs from remote areas to markets account for 20% of sales) hinder yield growth.

Significant Post-Harvest Losses: Due to a lack of sorting equipment, high impurity levels lead to export price discounts, resulting in an annual loss of approximately 15% of potential revenue.

II. The Critical Role of Sesame Cleaners in the Sesame Industry Chain

Nigerian sesame exports have extremely high impurity requirements (international standards ≤ 0.2%). Sesame cleaners effectively address this challenge through a combination of physical screening and airflow sorting:

1. Core Function Analysis

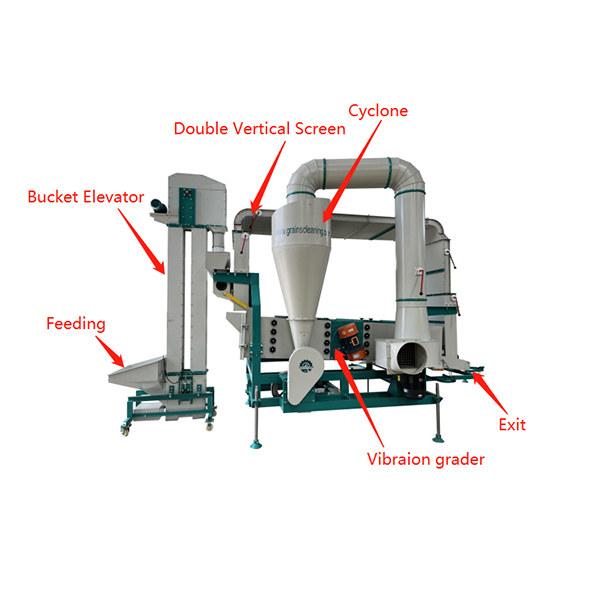

Multi-layer Screen Classification: Utilizes stainless steel screens with apertures of 1.2-1.8 mm to separate fine sand, weed seeds, and broken hulls. For example, Hebei Beibu Machinery’s double-layer air separation cleaner, equipped with four layers of screens, simultaneously removes large impurities (such as clods of soil) and small impurities (such as dust).

Negative Pressure Airflow Cleaning: A dual-fan system generates a strong airflow, removing lightweight straw debris, shrunken grains, and other impurities from the main stream. Certain models can adjust the air speed to 12-18 m/s, ensuring a light impurity removal rate exceeding 99%.

2. Increased Economic Value

Export Premium: After cleaning, the purity of sesame seeds increases from 85% to 99.5%, potentially increasing export prices by 20%-30%. Based on 2022 export volumes, if all cleaning machines were used, annual revenue could increase by $64 million.

Optimized Processing Efficiency: After cleaning, pre-processing time for sesame seeds entering the oil press can be reduced by 30%, reducing equipment wear and tear and increasing oil yield by 1-2 percentage points.

3. Technological Innovation Trends

Energy-Saving Design: Taobo cleaning machines utilize variable-frequency motors, reducing energy consumption by 30% compared to traditional equipment.

Modular Integration: Some models integrate stone removal and grading functions, occupying a small footprint and suitable for small and medium-sized processing enterprises.

The sustainable development of Nigeria’s sesame industry is highly dependent on the widespread adoption of sorting machines. Through technological innovation, policy support, and business model optimization, these machines can not only enhance export competitiveness but also drive the upgrading of the local processing industry, providing a new path to food security and increased income for farmers in arid regions.

Post time: Sep-22-2025