A bean polishing machine is a specialized piece of machinery used to clean and brighten the surface of beans. Its core function is to remove impurities such as dust, mud, and loose skin from the bean surface, improving its appearance and commercial value.

Core Working Principle: Polishing is achieved through a combination of mechanical friction and auxiliary cleaning. High-speed Cotton canvas inside the polishing chamber gently rub against the beans, removing surface contaminants. Some models can be used with a small amount of food-grade polishing agent or water to enhance the cleaning and brightening effect. Finally, impurities are separated from the finished product by a screen or airflow, simultaneously removing dust.

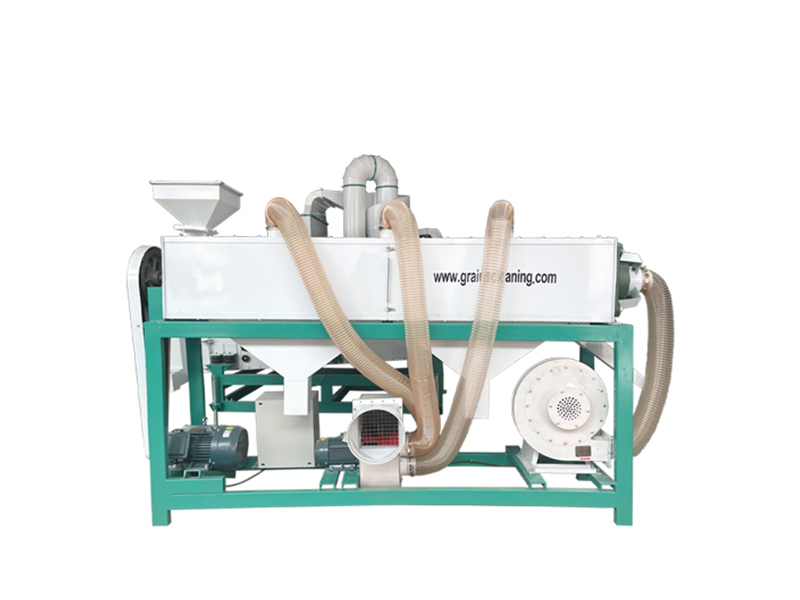

The beans polisher it consist of bucket elevator, dust collector, fan, Japan bearing, sieves, brand motors, Frequency converter.

Low speed no broken slope elevator: Loading grains and mung beans and beans to the polishing machine without any broken.

Stainless steel surface : Used for food processing.

Frequency converter :Adjusting the frequency for adjusting the speed of the beans and mung beans, and rice.

Polishing Process for Kidney Beans:

Feeding Stage: Kidney beans are evenly fed into the polishing chamber through the feed hopper. The feeding speed can be adjusted via a valve to prevent material accumulation.

Polishing Stage: Abrasive components such as brushes and rubber rollers inside the polishing chamber rotate at high speed, creating gentle friction against the surface of the kidney beans. Simultaneously, some equipment sprays a small amount of water or food-grade polishing agent to help remove stubborn stains and enhance gloss.

Separation Stage: After polishing, the kidney beans are carried by airflow or a conveyor into the separation zone. Impurities and dust are separated from the clean beans by a screen or airflow.

Discharge and Dust Removal: Clean kidney beans are discharged from the outlet. The separated dust is collected by a dust collection device to prevent environmental pollution.

Applicable Legumes and Materials:

Main Legumes: Kidney beans, red beans, mung beans, peas, lentils, chickpeas, broad beans, black beans, etc.

Extended Materials: Small grains (such as millet, quinoa), oilseeds (such as sesame, rapeseed), nuts (such as peanuts, crushed almonds).

Key Advantages:

Excellent Cleaning Effect: Removes over 90% of surface dust and minor imperfections, significantly improving the gloss of beans.

Low Damage Rate: Employs flexible grinding components and adjustable speed to minimize bean breakage and surface damage.

High Efficiency: Small and medium-sized models can produce 1-5 tons/hour, while large models can reach over 10 tons/hour, adapting to different scale needs.

Easy Operation: Simple structure; screens and grinding components can be quickly replaced, facilitating maintenance.

Due to the collecting the beans from the farm, there always are dust in the surface of the beans, so we need polishing to remove all the dust from surface of beans, to keep the bean clean and shinny, so that can improve the value of the beans, For our beans polishing machine and kidney polisher, there is big advantage for our polishing machine, As we known when the polishing machine working, always there some good beans will be broken by the polisher, so Our design it is for reduce the broken rates when the machine running, The broken rates can not over 0.05%.

It is suitable for various beans, it named as beans polisher, mung beans polisher, kidney beans polisher, rice polisher, and soya beans polisher.

Base on safe, easy to use, high efficiency and simple structure, this machine used and accepted by farmers around the world.

Post time: Nov-20-2025