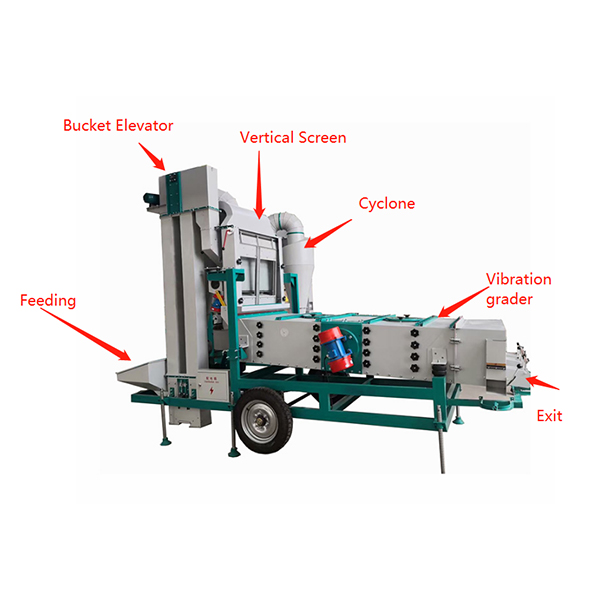

A pneumatic screen cleaner is a device that combines “air-powered impurity removal” with “screen grading” to clean and grade materials. It is widely used in the grain, seed, and feed industries.

I. Core Working Principle The equipment relies on the coordinated operation of two main systems to clean materials.

Air-powered Cleaning System: A fan generates a controllable airflow, separating impurities based on their density difference.

Lighter impurities (such as dust, straw fragments, and empty grains) are carried away by the airflow and discharged from the discharge port.

Heavier, qualified materials (such as plump seeds and grain pellets) sink in the airflow and enter the screen grading stage.

Screen Grading System: Multiple layers of screens with different apertures separate materials based on particle size differences.

Upper Screen (Large Aperture): Intercepts impurities larger than qualified materials (such as large stones and long straws), discharging them from the large impurity outlet.

Middle/lower layer screen (small aperture): Allows qualified materials to pass through while letting in impurities smaller than the materials (such as fine sand and fragments), which are then discharged from the fine impurity outlet.

To achieve a more thorough cleaning of chia seeds, the following cleaning equipment can be used in conjunction with an air-screen cleaner:

* **Gravity Destoner:** While air-screen cleaners primarily rely on airflow and particle size for cleaning, gravity destoners utilize the difference in specific gravity between the material and impurities for further separation. Chia seeds have a different specific gravity than stones, metals, and other heavy impurities. The gravity destoner removes these heavier impurities, further improving the purity of the chia seeds.

* **Grading Screen:** Grading screens offer advantages such as stable operation, a fully enclosed structure, and anti-clogging features. They typically use a vibrating motor and springs to generate vibration. The motor produces a radially varying excitation force, driving the screen box to vibrate in an approximately circular motion. Material on the screen is thrown upwards by the upward force of the screen surface, travels a distance, and then falls back onto the screen surface. Material smaller than the screen aperture passes through the screen and enters the under-screen chute. This process is repeated, completing the grading and screening process as the material moves from the inlet to the outlet.

Polishing machine: A polishing machine can remove dust, mold, and other impurities from the surface of chia seeds, increasing their smoothness and shine. For chia seed products with high appearance quality requirements, a polishing machine is a good choice. In addition, a polishing machine can also serve as a pre-processing step for air-screen cleaning machines, removing awns and other imperfections from the surface of chia seeds to facilitate subsequent cleaning operations.

The air-screen cleaner has a wide range of applications. Besides cleaning chia seeds, it can also clean most grains and legumes, primarily for applications requiring impurity removal.

Grain Processing: Removes straw, stones, and dust from raw grains such as wheat, rice, and corn, preparing them for subsequent milling and grinding.

Seed Treatment: Removes impurities and grades vegetable seeds, flower seeds, and crop seeds (such as chia seeds and sunflower seeds), improving seed purity and germination rate.

Cash Crop Processing: Processes crops such as peanuts, soybeans, and sesame, removing impurities and screening for different particle sizes to meet various processing needs.

If you have materials that need processing, please contact us for machine details!

Post time: Oct-29-2025