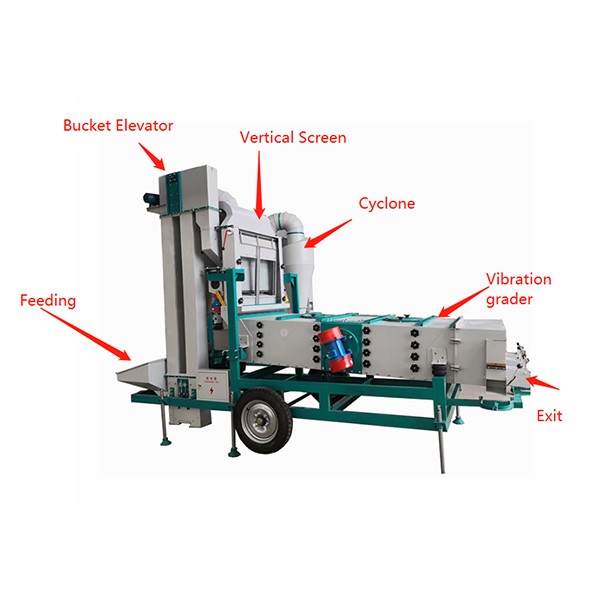

The air screen cleaner is a product that integrates lifting, air selection, screening and environmentally friendly dust removal.

When using air screen cleaner to screen soybeans, the key is to balance the “wind selection intensity” and “screening accuracy” while protecting the integrity of the soybeans.

Combining the physical characteristics of soybeans and the working principle of the equipment, strict control is carried out from multiple aspects

1、Preparation before screening and parameter debugging

(1) Check whether the bolts in each part are loose, whether the screen is taut and damaged, whether the fan impeller rotates flexibly, and whether the discharge port is unobstructed.

(2) Run the test at no load for 5-10 minutes to observe whether the amplitude and frequency of the vibrating screen are stable and whether the fan noise is normal.

2、Screen configuration and replacement

The sizes of upper and lower sieve holes match. Check the sieve regularly and replace it immediately if it is damaged or its elasticity decreases.

3、Air volume control and impurity handling

Air duct pressure balance and impurity discharge path optimization.

4、Special considerations for soybean characteristics

(1) Avoid soybean damage

The soybean seed coat is thin, so the vibration amplitude of the vibrating screen should not be too large.

(2) Anti-clogging treatment:

If the screen holes are clogged, brush them gently with a soft brush. Do not hit them with hard objects to avoid damaging the screen.

5、Equipment maintenance and safe operation

Daily maintenance: After each batch of screening, clean the screen, fan duct and each discharge port to prevent mildew or blockage.

Safety regulations: When the equipment is running, it is prohibited to open the protective cover or reach out to touch the screen surface, fan and other moving parts.

By precisely adjusting the wind speed, screen aperture and vibration parameters, and combining the physical properties of soybeans to dynamically optimize the operation, it is possible to efficiently remove impurities such as straw, shrunken grains, and broken beans, while ensuring the purity and quality of the screened soybeans to meet the different needs of eating, processing or seed propagation. During operation, attention should be paid to equipment maintenance and safety regulations to improve equipment service life and production efficiency.

Post time: Jul-02-2025