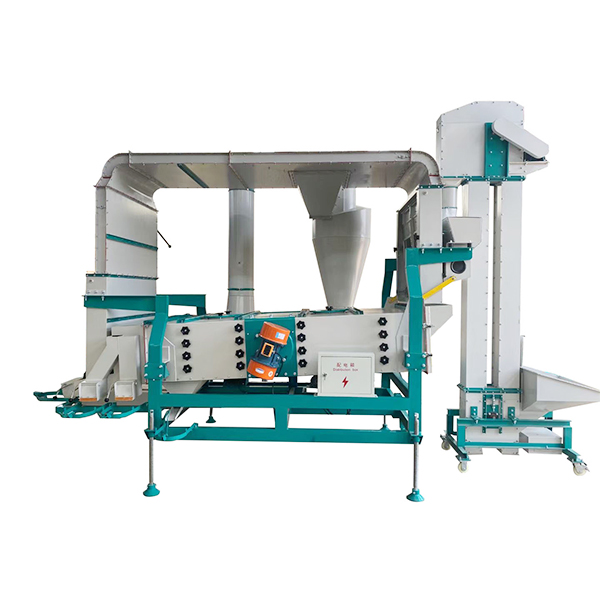

The air screen cleaner is a core equipment that uses the principle of combining wind sorting and screen filtration to remove impurities (such as straw, sand, gravel, empty grains, etc.) from crops. It is widely used in the post-harvest cleaning and processing of crops such as grains, beans, and cereals.

Different bean sizes directly affect the selection of sieves. For example, the sieves for soybeans, mung beans, and kidney beans are very different.

The air filter cleaner achieves material separation through the dual functions of “air separation” and “screening.” Both functions work in tandem, and neither is indispensable.

Air separation principle: The airflow generated by the fan separates material and impurities based on density differences. Light impurities (such as broken leaves and straw) are blown away by the airflow, while heavy impurities (such as sand and gravel) settle rapidly due to gravity, separating them from the crop kernels. Full kernels fall smoothly onto the screen surface with the airflow.

Screening principle: The size differences of the screen mesh and the vibration of the screen surface separate material and impurities based on their size. Impurities smaller than the screen aperture (such as shrunken grains and small sand and gravel) fall through the screen aperture, while full kernels larger than the screen aperture move along the screen surface and enter the next stage.

1. Screen Configuration: Focus on “Bean Size” and Design by “Impurity Level”

The key to screen configuration lies in aperture accuracy and the number of screen layers. First, determine the target bean size range, then prioritize and intercept impurities based on size. Typically, a combination of 2-3 screen layers is used.

Step 1: Determine the Core Screen Aperture (Based on Bean Variety)

Bean particle sizes vary significantly. First, measure the “minimum filled particle size” and “maximum filled particle size” of the target beans to use as a benchmark for the screen aperture.

Small beans (such as mung beans and adzuki beans, with a particle size of 3-5mm):

Pre-screening (first layer): Select a screen with an aperture 1-2mm larger than the maximum particle size (e.g., 6-7mm). This will retain large impurities (such as bean pods, large straw, and clods of soil) while allowing the beans and small impurities to pass through. Main sieve (second layer): Choose a sieve with a pore size 0.5-1mm smaller than the minimum full bean size (e.g., 2.5-4mm). This allows small impurities (such as shriveled beans, broken beans, and small gravel) to pass through, retaining full beans.

Medium-sized beans (such as kidney beans and chickpeas, with a particle size of 6-10mm):

Pre-sieve (first layer): Choose a sieve with a pore size of 11-12mm to intercept large impurities.

Main sieve (second layer): Choose a sieve with a pore size of 5.5-9mm to separate small impurities from full beans.

Large-sized beans (such as soybeans and black beans, with a particle size of 8-12mm):

Pre-sieve (first layer): Choose a sieve with a pore size of 13-14mm to intercept large impurities.

Main sieve (second layer): Choose a sieve with a pore size of 7.5-11mm to separate small impurities from full beans. Step 2: Add Screening Layers Based on Impurity Type

For impurities with “shallow impurities” (such as sand and gravel, or shrunken grains similar in size to the beans), add a “density screen” after the main screen to further separate them by utilizing density differences rather than relying solely on aperture size.

For impurities with “fibrous impurities” (such as broken bean stalks and hulls), add a “coarse-mesh screen” (with apertures 3-5mm larger than the pre-screen) before the pre-screen to capture long-fiber impurities and prevent clogging of subsequent screens.

2. Vibration Parameters: Focus on “material flowability” and dynamically adjust according to “bean characteristics.”

Vibration parameters (vibration frequency and amplitude) should be adjusted based on the bean’s moisture content and particle hardness. The key is to ensure even material movement across the screen, without accumulation or breakage.

Vibration Frequency: Adjusted based on “moisture content + flowability.”

Low moisture content (≤12%, dry) and good flowability (such as soybeans and mung beans):

Select a frequency of 18-22Hz to increase material movement across the screen, improving processing efficiency while also preventing excessive vibration wear caused by particles remaining on the screen for extended periods.

High moisture content (>12%, damp) and prone to sticking (such as kidney beans and chickpeas, whose skins absorb moisture and stick easily):

Select a frequency of 12-16Hz to slow down the movement, allowing the particles sufficient time to separate and preventing sticking that can clog the screen and cause localized accumulation. Amplitude: Adjust based on the “frequency + bean hardness” balance.

Follow the principle of “high frequency, low amplitude, low frequency, high amplitude,” taking into account bean hardness to prevent crushing:

High frequency (18-22Hz) with:

Small amplitude (3-5mm) is suitable for hard beans (such as soybeans and black beans), reducing kernel impact and crushing caused by high-frequency vibration.

Low frequency (12-16Hz) with:

Large amplitude (5-8mm) is suitable for beans with medium hardness or those prone to sticking (such as mung beans and kidney beans). The larger vibration amplitude breaks up sticking and promotes material flow.

Special Cases: If localized accumulation occurs on the screen surface, increase the amplitude by 1-2mm or fine-tune the screen surface tilt angle (usually 5-8°, with a smaller tilt for small beans and a larger tilt for large beans) to aid flow.

If you need to customize the machine’s capacity, adjust components for specific beans varieties, or learn more about installation and after-sales support, feel free to contact our team. We provide tailored solutions to meet your unique processing needs.

Post time: Oct-20-2025