Double air screen cleaner very suitable for cleaning sesame and sunflowers and chia seed, Because it can remove the dust leaves and light impurities very well. The double air screen cleaner can clean light impurities and foreign objects by vertical air screen, Then vibrating box can remove big and small impurities and foreign objects. Meanwhile the material can be separate into big, medium and small size when though different size sieves. This machine can remove stones also, The secondary air screen can remove dust from final products again for improve the sesame purity.

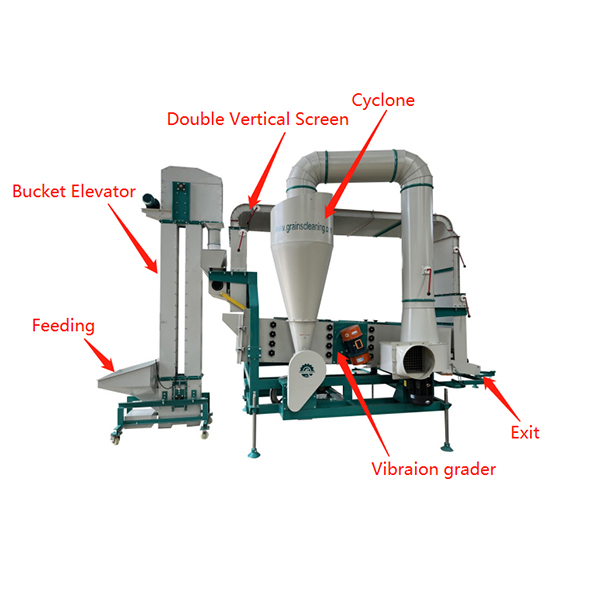

Whole Structure of the Machine

It consists of Bucket Elevator, Dust collector, double Vertical air Screen, vibration box and Sieve.

Put the materials into the hopper of elevator . The no crushing elevator will send the materials into the machine . At first , it will go through the back air screen , or someone called air separator . Here the air will take out the light impurities such as dust , small leaves , shells , strew, etc .

Then , the materials will go through the vibration grader . the vibration grader have 4 layer sieves with different size of holes . it will remove the big and small impurities .

After that , the materials will go through another air screen again to remove the light impurities .

To use this machine , you only need to adjusting the air handle for the two air screen . So it is very easy to operate .

The core operating steps for cleaning corn with an air-screen cleaner are “preparation – debugging – operation – finishing”. Following the process ensures cleaning efficiency and corn quality. The specific steps are as follows:

1. Pre-start Preparation

Check Equipment Status: Ensure the screen is intact and undamaged, the fan blades are not deformed or entangled with foreign objects, and all connections (such as the feed hopper and discharge port) are secure and not loose.

Clean Equipment Residue: Remove any residual material and impurities from the machine to prevent mixing of different batches of corn or clogging of the screen.

Adapt to Corn Characteristics: Replace the screen with one of the appropriate aperture size according to the corn kernel size (the upper screen aperture should be slightly larger than the corn kernels, and the lower screen slightly smaller). Adjust the fan speed according to the corn’s moisture content.

Check Auxiliary Facilities: Ensure a stable power connection, that the impurity collection bag and finished product receiving device are properly installed, and that there is no risk of leakage.

2. Parameter Adjustment (Key Steps)

No-load Test Run: Start the equipment and allow the screen and fan to run unloaded for 5-10 minutes. Observe whether there is any abnormal noise or vibration, and whether the fan airflow is uniform.

Wind Speed Adjustment: First, adjust the wind speed to medium. Fine-tune it based on the cleaning effect to avoid excessive wind speed blowing away whole corn kernels, or too low a wind speed causing light impurities to remain.

Vibration Frequency Adjustment: Adjust the screen vibration frequency through the control panel. The ideal frequency is for the corn to be evenly distributed and move slowly on the screen surface, avoiding excessive frequency that could cause corn to splatter.

Small-batch Test: Input a small amount of corn (approximately 5-10 kg) and observe the discharge. Qualified corn should discharge smoothly from the finished product outlet, while large and small impurities should be discharged from their respective impurity outlets, with no obvious mixing.

3、Formal Operation

Uniform Feeding: Corn is fed evenly through the feed hopper, avoiding large-scale feeding at once to prevent screen clogging or insufficient airflow.

Real-time Monitoring: Observe three key areas during operation.

Feed Inlet: No blockage; corn is evenly spread on the screen surface.

Discharge Outlet: No obvious impurities in the finished corn; no whole corn kernels are mixed into the impurity outlet.

Equipment Status: No abnormal heating or noise; impurity collection bag is not overloaded.

4、Shutdown and Finishing Steps

Gradual Shutdown: First, stop feeding, allow the equipment to continue running for 3-5 minutes to empty any remaining corn and impurities from the machine, then turn off the power.

Cleaning and Maintenance: Disassemble and clean the impurity collection bag. Use a soft brush to clean any residual material from the screen surface to prevent material from clumping and affecting future use.

Inspection and Storage: Re-inspect the screen, fan, and other components for wear and tear. Replace any damaged parts promptly. Disconnect the power supply and ensure the equipment is protected from dust and moisture.

Post time: Oct-31-2025