The air-screen cleaner operates primarily based on the principles of air separation and screening. After entering the feed hopper, the material falls evenly onto the upper screen. The airflow generated by the blower carries away lightweight impurities such as straw fragments and shriveled grains, while heavier rapeseed remains on the screen surface. Simultaneously, screens with different apertures screen the rapeseed, blocking larger stones and clods of soil during the initial screening, while smaller impurities are removed in the subsequent fine screening process.

I. Rapeseed Cleaning Workflow The rapeseed cleaning machine processes rapeseed through 5 core steps, performed in sequence:

Feeding Buffer: The rapeseed to be cleaned enters the equipment from the hopper. The adjustment device at the bottom of the hopper controls the feed rate, ensuring the material enters the next stage evenly and stably, avoiding incomplete cleaning due to excessive feeding.

Initial Air Classification: After the material falls into the air duct, the airflow generated by the blower blows towards the rapeseed. Light impurities such as straw fragments, shriveled kernels, and dust are carried away by the airflow and fall into a special light impurity collection bag; heavier, plump rapeseed continues to move downwards and enters the screening stage.

Multi-layer Screening: After entering the screen box, the rapeseed passes through 2-3 layers of screens with different aperture sizes (the aperture gradually decreases from top to bottom).

Upper Screen: Blocks large particles such as stones, large clods of soil, and long straw. These impurities are discharged from the discharge port at the end of the screen.

Middle screen: Screens out plump rapeseed that meets the requirements, which falls directly into the finished product collection area.

Lower screen: Filters out small soil particles, broken seeds, and other fine impurities, which are discharged from the fine impurity outlet at the bottom of the equipment.

Secondary air separation (optional): Some models add a secondary air separation stage after screening to further remove any remaining light impurities from the finished rapeseed, further improving the purity of the cleaned product.

Finished product collection: The purified rapeseed, after air separation and screening, finally enters the storage silo or packaging bag through the discharge port, completing the entire cleaning process.

Features

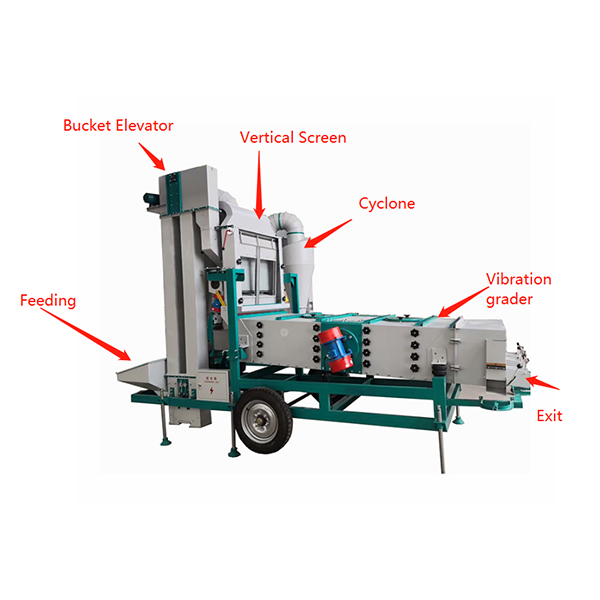

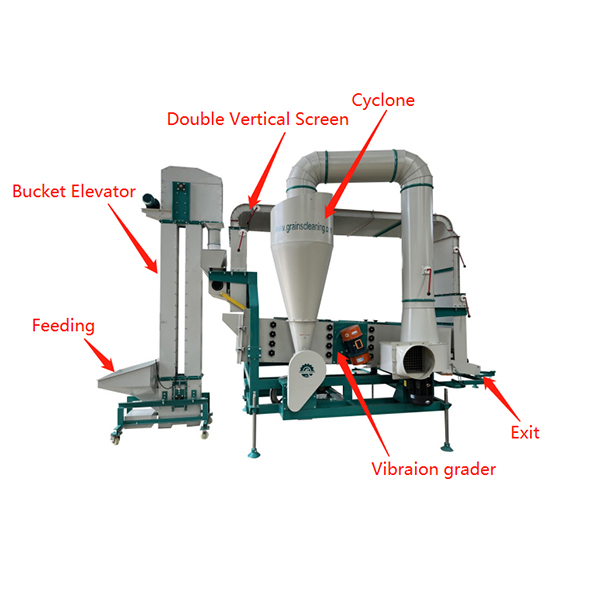

● The seed and grains air screen cleaner consists of dust collector , Vertical screen, vibration box sieves and Non-broken low speed bucket elevator.

● It is widely used in seed processing and grains processing plant and Pulses processing plant as the Pre-cleaner.

● The material can be classified into big, medium and small particles with different layers of sieves ( Stainless steel sieves ).

Advantage

● High Purity :98%-99% purity

● 5-10Ton per hour cleaning capacity for cleaning different seeds and clean grains.

● Non broken low speed bucket elevator without any damage for the seeds and grains.

● High quality motor for seeds cleaning machine ,high quality Japan bearing .

● Easy to operate with high performance .

The application scope of the air-screen cleaner is mainly divided into two categories: “crop type” and “application scenario,” as detailed below:

1. Applicable Crop Types: Besides the core crop rapeseed, it can also be used for cleaning various granular crops, including but not limited to:

Grain Crops: Wheat, rice, corn, soybeans, sorghum, millet, etc.

Oil Crops: Peanuts (shelled), sesame, sunflower seeds (shelled), etc.

Seed Crops: Various vegetable seeds (such as cabbage seeds, cucumber seeds), forage seeds, etc., which can be used for seed selection to improve germination rates.

2. Applicable Application Scenarios:

Small-scale use by farmers: Small-scale air-screen cleaners (e.g., with a production rate of 200-500 kg/h) are compact and mobile, suitable for farmers to perform preliminary cleaning of their own harvested rapeseed to remove field impurities.

Grain and oil processing plants: Medium or large-scale cleaning machines (e.g., with a production rate of 5-20 t/h) can be integrated into rapeseed oil pressing production lines as a pretreatment stage to ensure the purity of raw materials entering the oil pressing process and improve oil quality.

Seed processing enterprises: High-precision air-screen cleaning machines (with grading function) can grade and screen seeds, selecting uniformly sized and plump kernels as high-quality seeds to meet seed sales demands.

Post time: Nov-03-2025