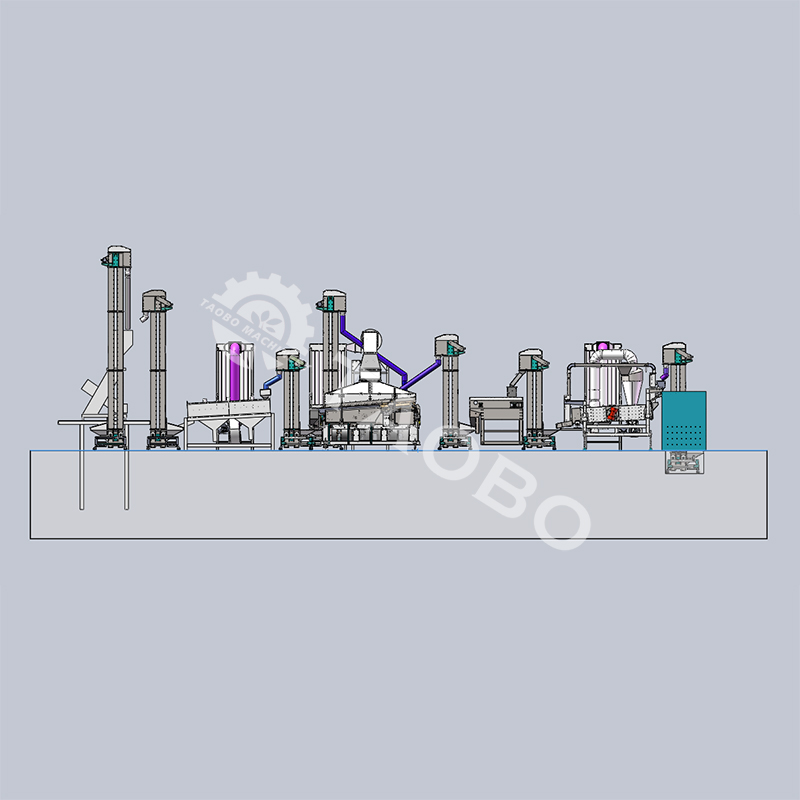

Product Composition

Magnetic separator, specific gravity destoner, specific gravity selection machine, polishing machine, vibrating bean cleaning production line consists of air screen cleaning machine, grading screen, quantitative packaging scale, pulse dust collector, bag dust collector, elevator and other auxiliary equipment Composed of parts.

working principle

The raw grain first passes through an air screen cleaning machine to remove light impurities, large impurities, and small impurities. Then it passes through a magnetic separator, a destoner, and a pycnometer to remove impurities such as soil, stones, and mildewed grains, and then enters the polishing machine for friction. Make it brighter, then enter grading and screening into large, medium and small particles, and finally carry out quantitative packaging according to different packaging requirements.

Product advantages

1. PLC automatic control and automatic alarm device facilitate customers’ overall control;

2. The main components are selected from domestic and foreign brand products, and the production line equipment operates stably;

3. Contains a complete set of dust removal systems to collect and process dust in a centralized manner, ensuring cleanliness and environmental protection;

4. Each part of the structure is connected by bolts to reduce installation and transportation costs;

5. The production process can be comprehensively designed according to the site, and the equipment layout can facilitate maintenance and repair.

It is suitable for the processing of various grains and legumes such as mung beans, red adzuki beans, and kidney beans.

Post time: Jan-08-2024