Original China Best Quality Rice Grain Colour Sorting Mung Beans Color Sorter

We often stick to the basic principle “Quality 1st, Prestige Supreme”. We are fully committed to giving our shoppers with competitively priced excellent products and solutions, prompt delivery and skilled provider for Original China Best Quality Rice Grain Colour Sorting Mung Beans Color Sorter, We wish to take this opportunity to ascertain long-term business interactions with clientele from all over the entire world.

We often stick to the basic principle “Quality 1st, Prestige Supreme”. We are fully committed to giving our shoppers with competitively priced excellent products and solutions, prompt delivery and skilled provider for , Our items are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is “to continue to earn your loyalty by dedicating our efforts to the constant improvement of our products and solutions and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate”.

Introduction

It used on the rice and paddy , beans and pulses , wheat , corn, sesame seeds and coffee beans and others.

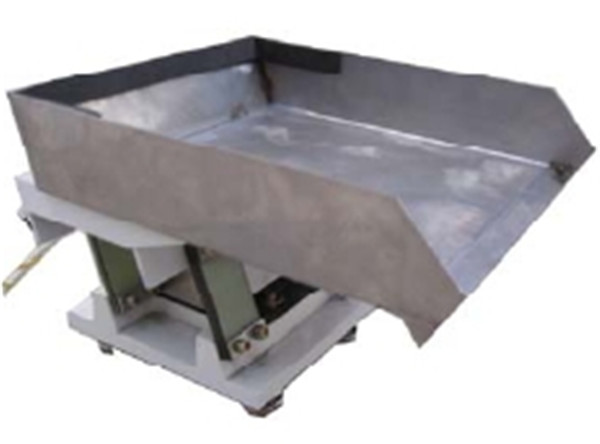

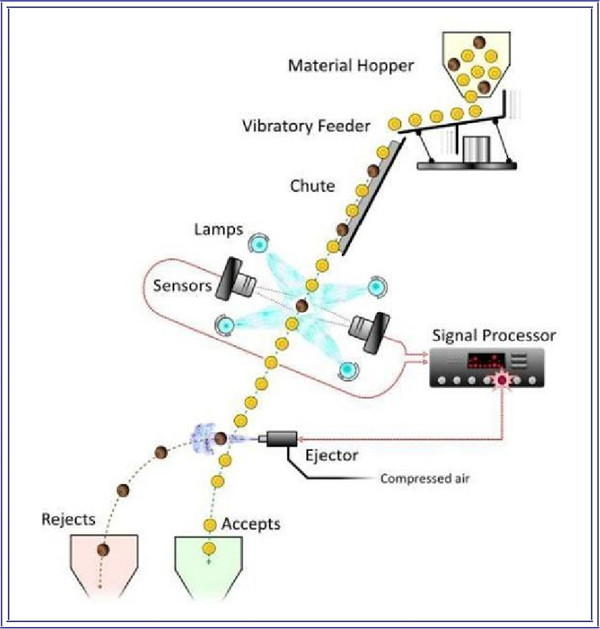

Vibration feeding device-vibrator

Feeding vibration mechanism, the selected material is vibrated and conveyed to the pass through the hopper road. The control system controls the large amount of vibration of the vibrator through pulse width adjustment Small, in order to achieve the adjustment of the flow of the whole machine

Unloading chute device-channel

The aisle where the material accelerates down to ensure that the material entering the sorting room is separated The cloth is uniform and the speed is consistent, so as to ensure the color selection effect.

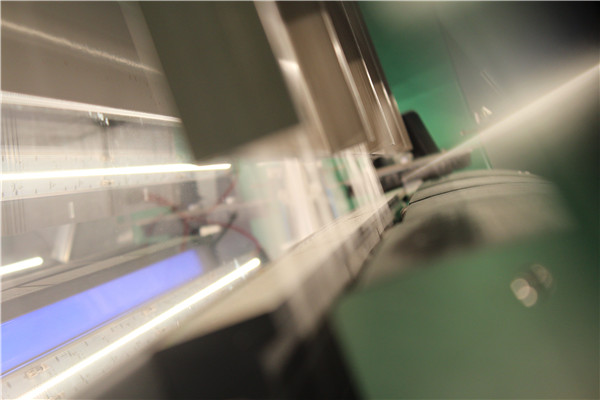

Optical system-sorting room

Material collection and sorting device, light source, background adjustment device, CCD

It is composed of camera device, observation and sampling window, and dust removal device.

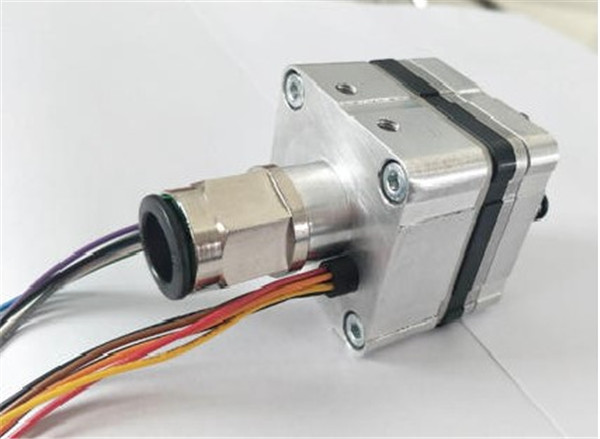

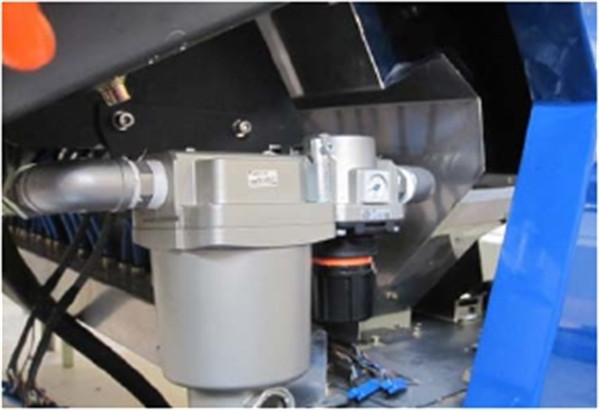

Nozzle system-spray valve

When the system recognizes a certain material as a defective product, the spray valve ejects gas to eliminate The material. The picture below shows the nozzles that are easily visible on the machine.

Control device-electrical control box

This department The system is responsible for automatically collecting, amplifying, and processing photoelectric signals, and sending out commands to drive the spray valve through the control part to spray out compression Air blows out the rejects, completes the color selection function, and achieves the purpose of selection

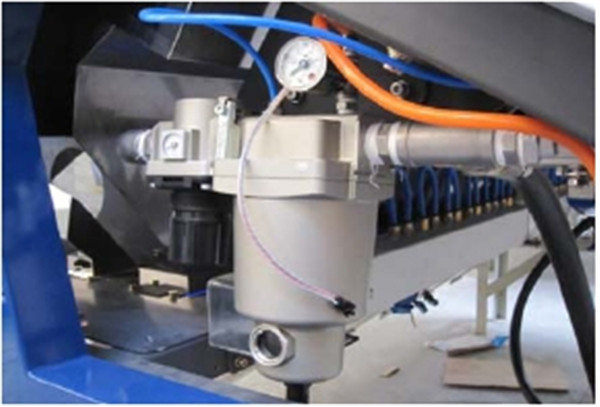

Gas system

Located on the left and right sides of the machine, it provides high cleanliness of compressed air to the whole machine.

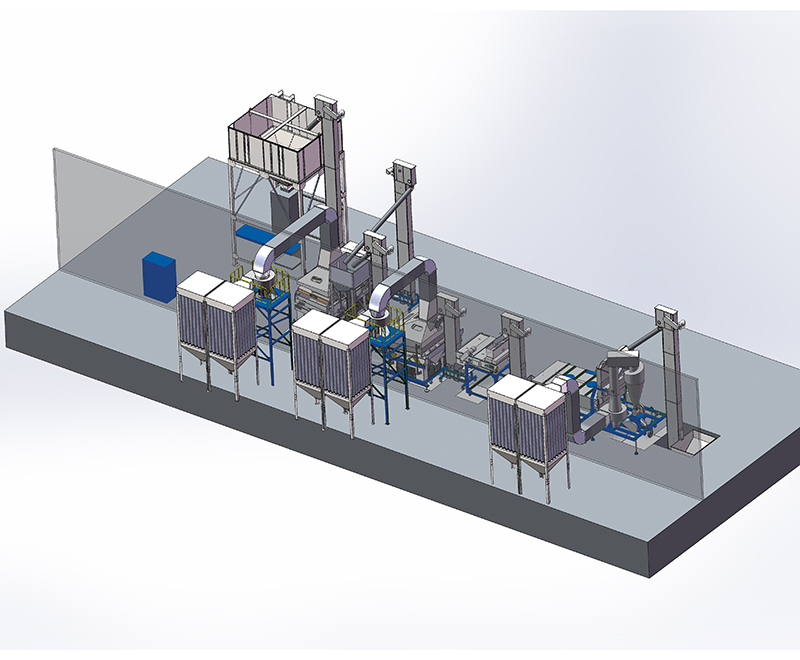

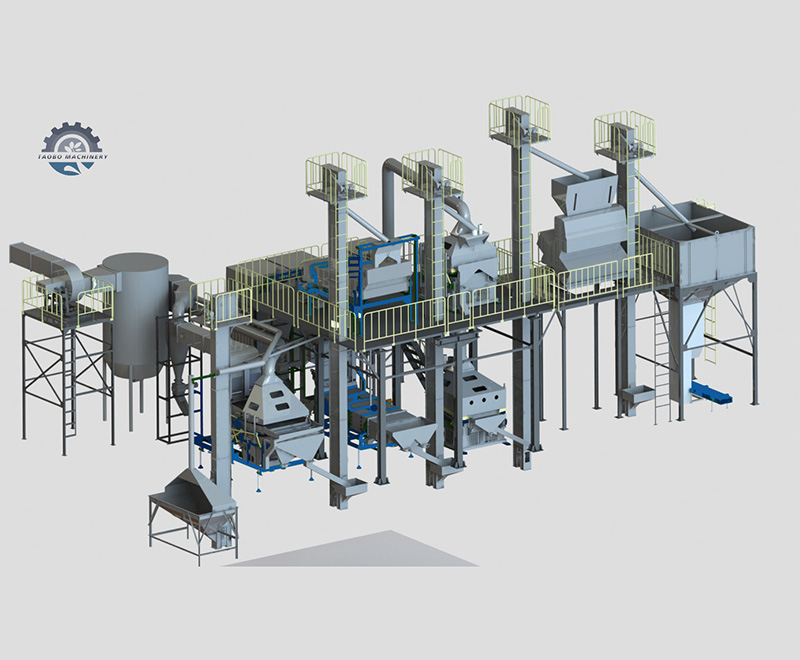

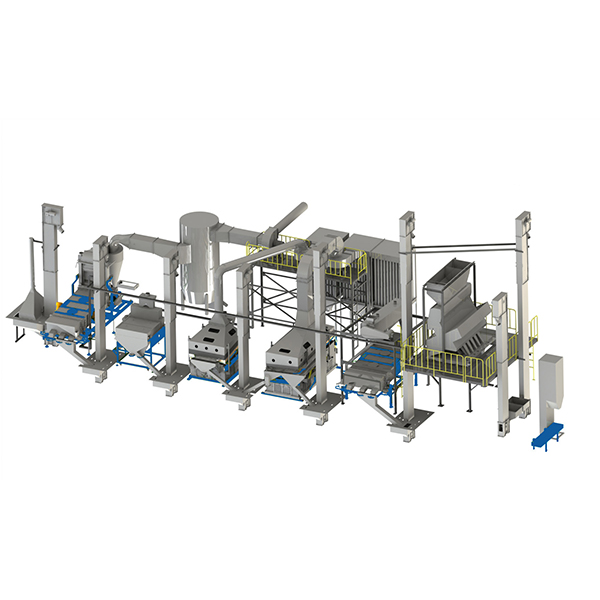

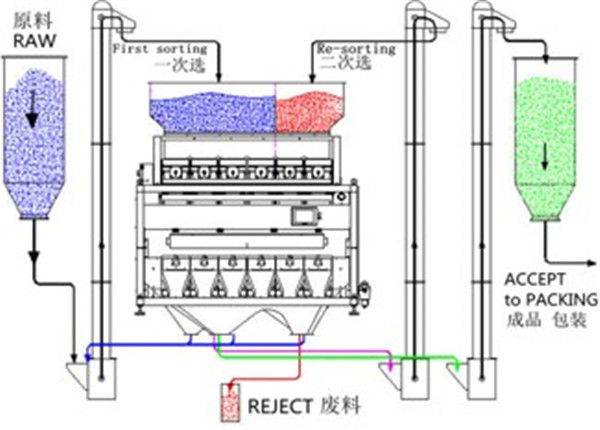

Whole Structure of the Machine

After the materials enter the color sorter from the top, the first color sorting is carried out. The qualified materials are the finished products. The selected reject materials are sent to the secondary color selection channel by the user through the lifting device for secondary color selection.The materials and qualified materials of the secondary color sorting directly enter the raw materials or return to the first through the lifting device prepared by the user . The secondary sorting is carried out for the second color sorting, and the rejected materials of the second color sorting are waste products. The process of the third color sorting is similar

Color sorter Working flow chat

The whole system

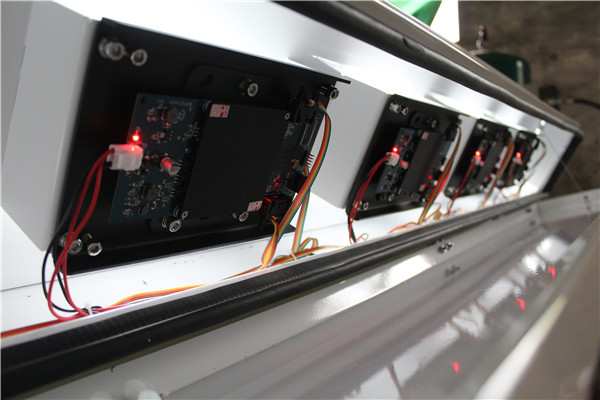

Details showing

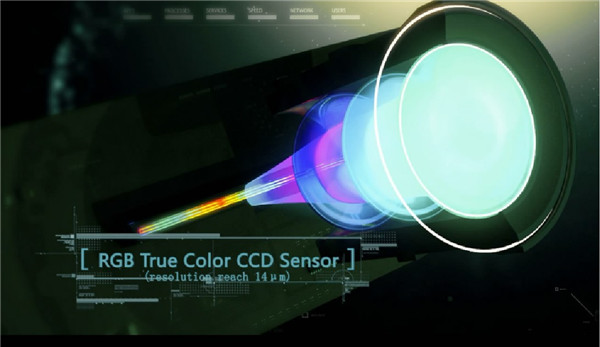

true color CCD image grabbing system

High-Quality Solenoid Valve

Best Cpu For Whole System

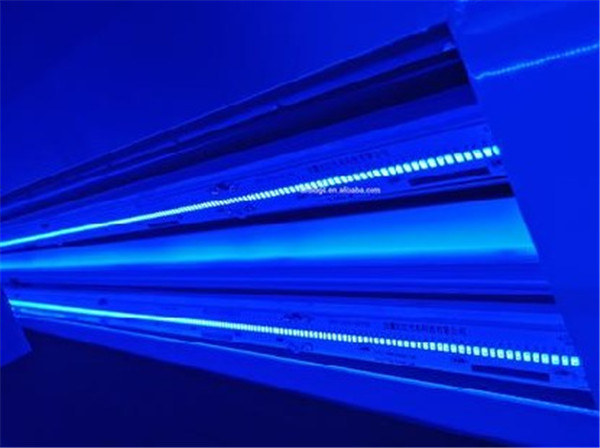

LED Light

Technical specifications

|

Model |

Ejectors (pcs) |

Chutes (pcs) |

Power (Kw) |

Voltage(V) |

Air Pressure (Mpa) |

Air Consumption (m³/min) |

Weight(Kg) |

Dimension (L*W*H,mm) |

| C1 | 64 | 1 | 0.8 |

AC220V/50Hz |

0.6~0.8 | < 1 | 240 | 975*1550*1400 |

| C2 | 128 | 2 | 1.1 |

AC220V/50Hz |

0.6~0.8 | < 1.8 | 500 | 1240*1705*1828 |

| C3 | 192 | 3 | 1.4 |

AC220V/50Hz |

0.6~0.8 | <2.5 | 800 | 1555*1707*1828 |

| C4 | 256 | 4 | 1.8 |

AC220V/50Hz |

0.6~0.8 | <3.0 | 1000 | 1869*1707*1828 |

| C5 | 320 | 5 | 2.2 |

AC220V/50Hz |

0.6~0.8 | <3.5 | 1 100 | 2184*1707*1828 |

| C6 | 384 | 6 | 2.8 |

AC220V/50Hz |

0.6~0.8 | <4.0 | 1350 | 2500*1707*1828 |

| C7 | 448 | 7 | 3.2 |

AC220V/50Hz |

0.6~0.8 | <5.0 | 1350 | 2814*1707*1828 |

| C8 | 512 | 8 | 3.7 |

AC220V/50Hz |

0.6~0.8 | <6.0 | 1500 | 3129*1707*1828 |

| C9 | 640 | 10 | 4.2 |

AC220V/50Hz |

0.6~0.8 | <7.0 | 1750 | 3759*1710*1828 |

| C10 | 768 | 12 | 4.8 |

AC220V/50Hz |

0.6~0.8 | <8.0 | 1900 | 4389*1710*1828 |

Questions from clients

Why we need the color sorter machine ?

Now that the cleaning requirements are getting higher and higher, more and more color sorters are applied to the sesame and beans processing plant, especially the coffee bean processing plant and rice processing plant . The color sorter can effectively remove the different color material in the final coffee beans to improve purity .

After the processing with color sorter the purity can reach 99.99% . So that it can make your grains and rice and coffee beans more valuable.

We often stick to the basic principle “Quality 1st, Prestige Supreme”. We are fully committed to giving our shoppers with competitively priced excellent products and solutions, prompt delivery and skilled provider for Original China Best Quality Rice Grain Color Sorting Mung Beans Color Sorter, We wish to take this opportunity to ascertain long-term business interactions with clientele from all over the entire world.

Original optical sorter and cocoa bean sorting machine, Our items are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is “to continue to earn your loyalty by dedicating our efforts to the constant improvement of our products and solutions and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate”.