Short Lead Time for Rice Auto Packing Machine - Auto packing and auto sewing machine – Taobo

Short Lead Time for Rice Auto Packing Machine - Auto packing and auto sewing machine – Taobo Detail:

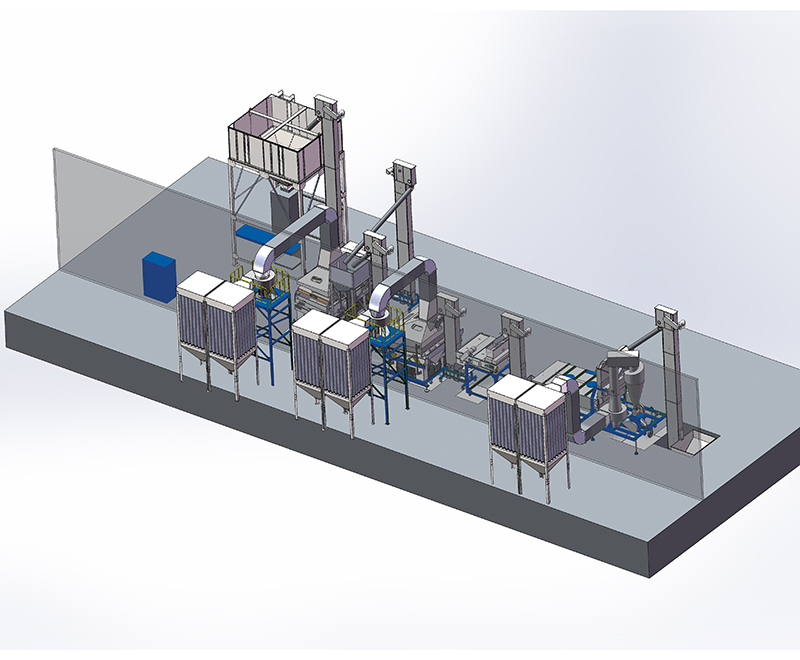

Introduction

● This auto packing machine consists of automatic weighing device, conveyor, sealing device and computer controller.

● Fast weighing speed, Precise measure, small space, convenient operation .

● Single scale and double scale, 10-100kg scale per pp bag .

● It has the auto sewing machine and auto cut threading .

Application

Applicable materials: Beans, pulses, maize, peanut, grain, sesame seeds

Production: 300-500bag/h

Packing Scope: 1-100kg/bag

Structure Of Machine

● One Elevator

● One Belt Conveyer

● One Air Compressor

● One Bag-sewing machine

● One Automatic Weighting Scale

Features

● belt conveyor speed is adjustable .

● High-precision controller, It can do the error ≤0.1%

● One key recovery function, for easy recover the fault of the machine.

● The small silos surface made by SS304 Stainless steel, which it is food grading use

● Use well known best quality parts, such as weighing controller from japan, low speed bucket elevator, and air control system

● Easy installation, auto weighing, loading, sewing and cutting threads. Only need one person to feed the bags. It will save human cost

Details showing

Air compressor

Auto sewing machine

control box

Technical specifications

|

Name |

Model |

Packing scope (Kg/bag) |

Power(KW) |

Capacity (Bag/H) |

Weight(KG) |

Oversize L*W*H(MM) |

Voltage |

|

Single scale of electric packing scale |

TBP-50A |

10-50 |

0.74 |

≥300 |

1000 |

2500*900*3600 |

380V 50HZ |

|

TBP-100A |

10-100 |

0.74 |

≥300 |

1200 |

3000*900*3600 |

380V 50HZ |

Questions from clients

Why we need the auto packing machine ?

Due to our advantage

High calculating precision, rapid packaging speed, stable function, easy operation.

Adopt advanced techniques on control instrument, sensor, and pneumatic components.

Advanced functions: automatic correction, error alarm, automatic error detection.

All components which have direct contact with bagging materials are made from stainless steel.

Where we are using the auto packing machine ?

Now more and more modern factories are using the beans and grains processing plant, If we want to achieve full automation, so from the beginning of pre-cleaner -the packing section, All the machine need to reduce the human being using, so automatic packaging machine are important and very necessary.

Generally, the advantages of automatic packaging machine scales can save labor cost. It used to require 4-5 workers at before, but now only It can be operated by one worker, and the output capacity per hour can reach 500 bags per hour.

Product detail pictures:

Related Product Guide:

We generally continually give you quite possibly the most conscientious shopper company, and the widest variety of designs and styles with finest materials. These endeavours include the availability of customized designs with speed and dispatch for Short Lead Time for Rice Auto Packing Machine - Auto packing and auto sewing machine – Taobo , The product will supply to all over the world, such as: Amsterdam, Kuala Lumpur, Liverpool, Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound solutions with good logistics service and economical cost. Depending on this, our solutions are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!